Practical Methods to Improve the Quality of Aluminum Die Castings

Content

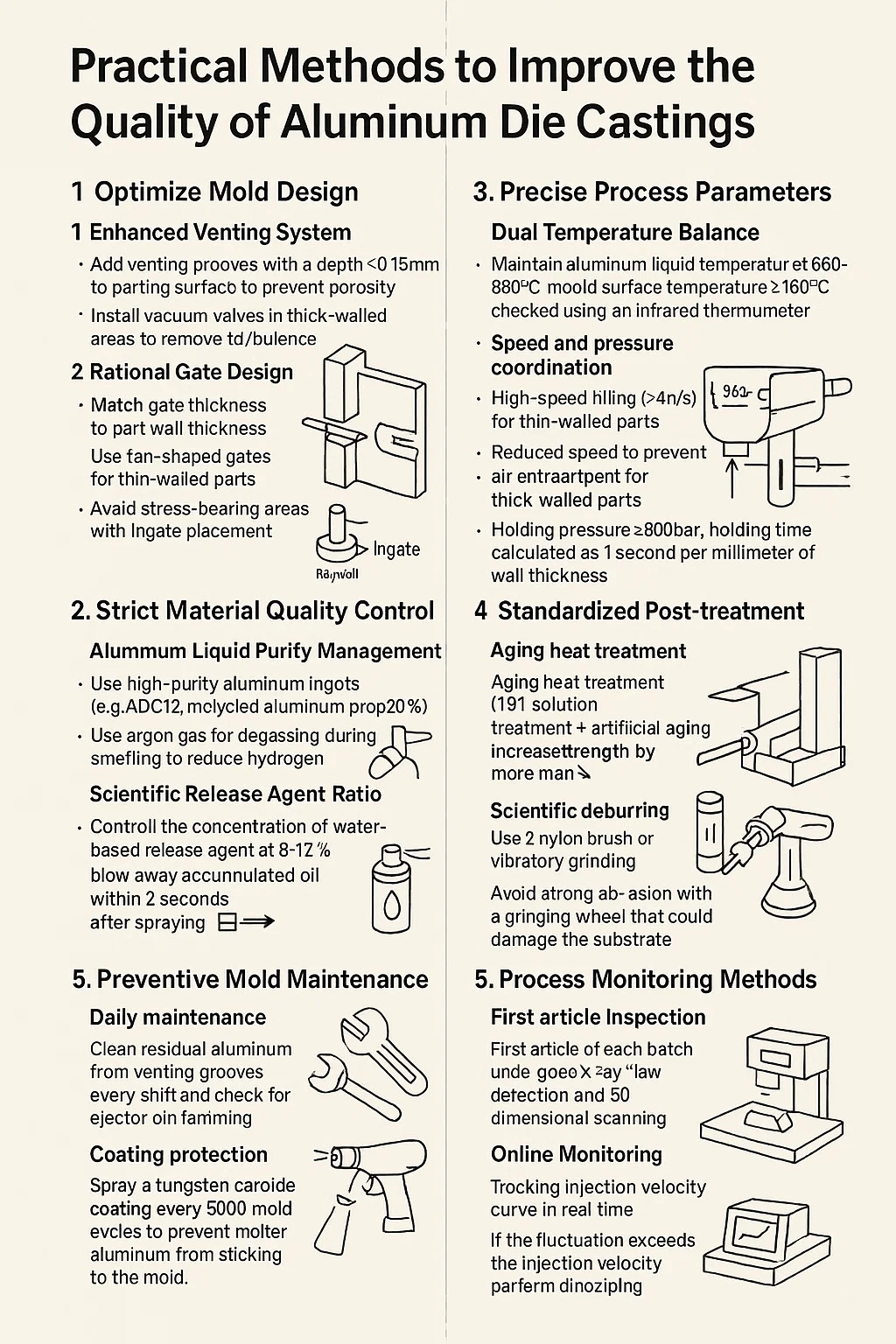

1. Optimize Mold Design

• Enhanced Venting System: Add venting grooves with a depth ≤0.15mm to the parting surface to prevent porosity.

Install vacuum valves in thick-walled areas to remove residual air from the mold cavity.

• Rational Gate Design: Match gate thickness to part wall thickness; use fan-shaped gates for thin-walled parts to prevent turbulence.

Avoid stress-bearing areas with ingate placement to reduce stress concentration.

2. Strict Material Quality Control

• Aluminum Liquid Purity Management: Use high-purity aluminum ingots (e.g., ADC12), with recycled aluminum proportion ≤20%.

Use argon gas for degassing during smelting to reduce hydrogen porosity.

• Scientific Release Agent Ratio: Control the concentration of water-based release agent at 8-12%, and blow away any accumulated oil within 3 seconds after spraying.

3. Precise Process Parameters

• Dual Temperature Balance: Maintain aluminum liquid temperature at 660-680℃ to avoid overheating oxidation or low-temperature cold shut-off.

Mold surface temperature ≥150℃ (checked using an infrared thermometer).

• Speed and pressure coordination: High-speed filling (>4m/s) for thin-walled parts, reduced speed to prevent air entrapment for thick-walled parts.

Holding pressure ≥600bar, holding time calculated as 1 second per millimeter of wall thickness.

4. Standardized post-treatment

• Aging heat treatment (T6): Solution treatment + artificial aging, increasing strength by more than 30%.

• Scientific deburring: Use a nylon brush or vibratory grinding; avoid strong abrasion with a grinding wheel that could damage the substrate.

• Surface passivation treatment: Acid pickling and passivation before anodizing to eliminate hidden corrosion points.

5. Preventive mold maintenance

• Daily maintenance: Clean residual aluminum from the venting grooves every shift and check for ejector pin jamming.

• Coating protection: Spray a tungsten carbide coating every 5000 mold cycles to prevent molten aluminum from sticking to the mold.

6. Process Monitoring Methods

• First Article Inspection: The first article of each batch undergoes X-ray flaw detection and 3D dimensional scanning.

• Online Monitoring: The injection velocity curve is tracked in real time. If the fluctuation exceeds the injection velocity curve, the machine is immediately stopped.

English

English русский

русский Español

Español