Web Menu

Product Search

Exit Menu

Product Series

Rice Transplanter Spare Parts

- Description

- Contact Us

Related Products

-

Driver Cover Case Crankcase

Cat:Aluminum Die Casting

The driver cover case crankcase is a pivotal component within the intricate machinery of an internal...

See Details -

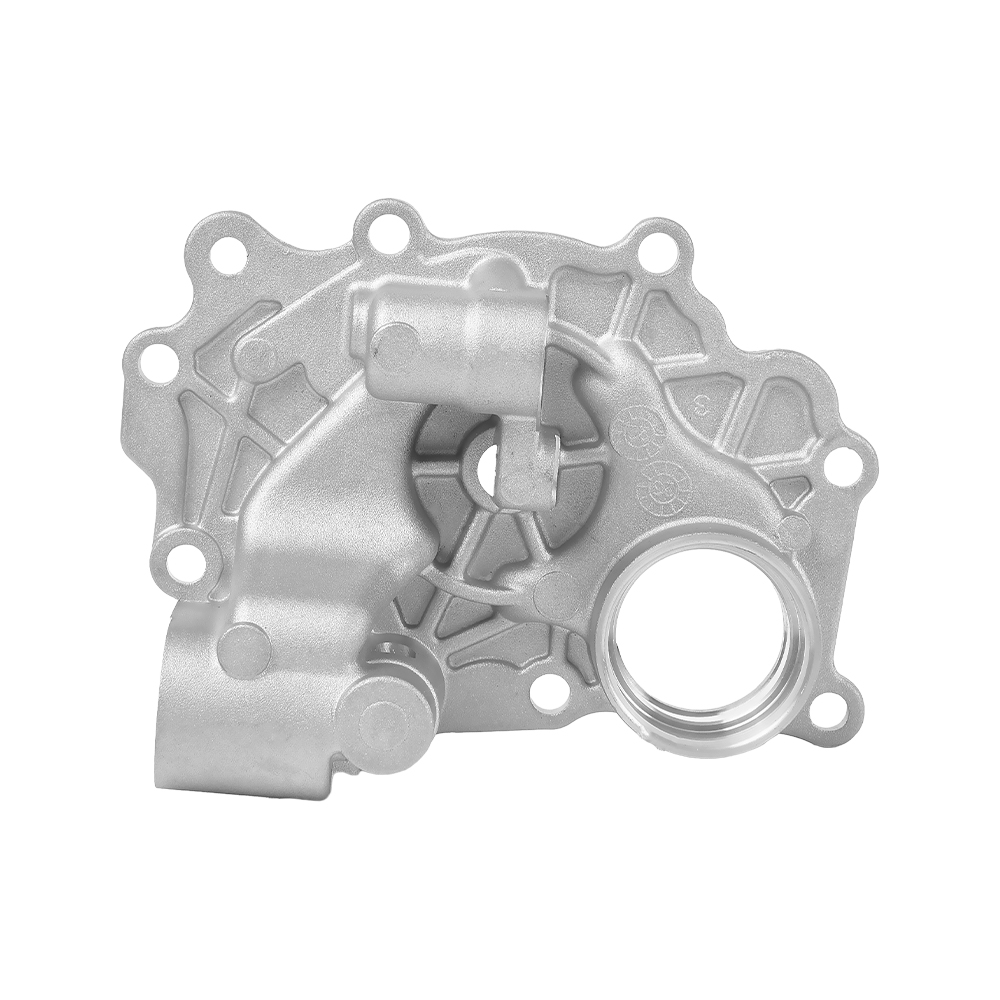

Auto Engine Aluminum Water Pump

Cat:Aluminum Die Casting

Auto Engine Aluminum Water Pump is a high-performance aluminum water pump designed specifically for ...

See Details -

Aluminum Cast Engine Water Pump

Cat:Aluminum Die Casting

Our aluminum alloy cast engine water pump is crafted from high-quality aluminum alloy material, unde...

See Details -

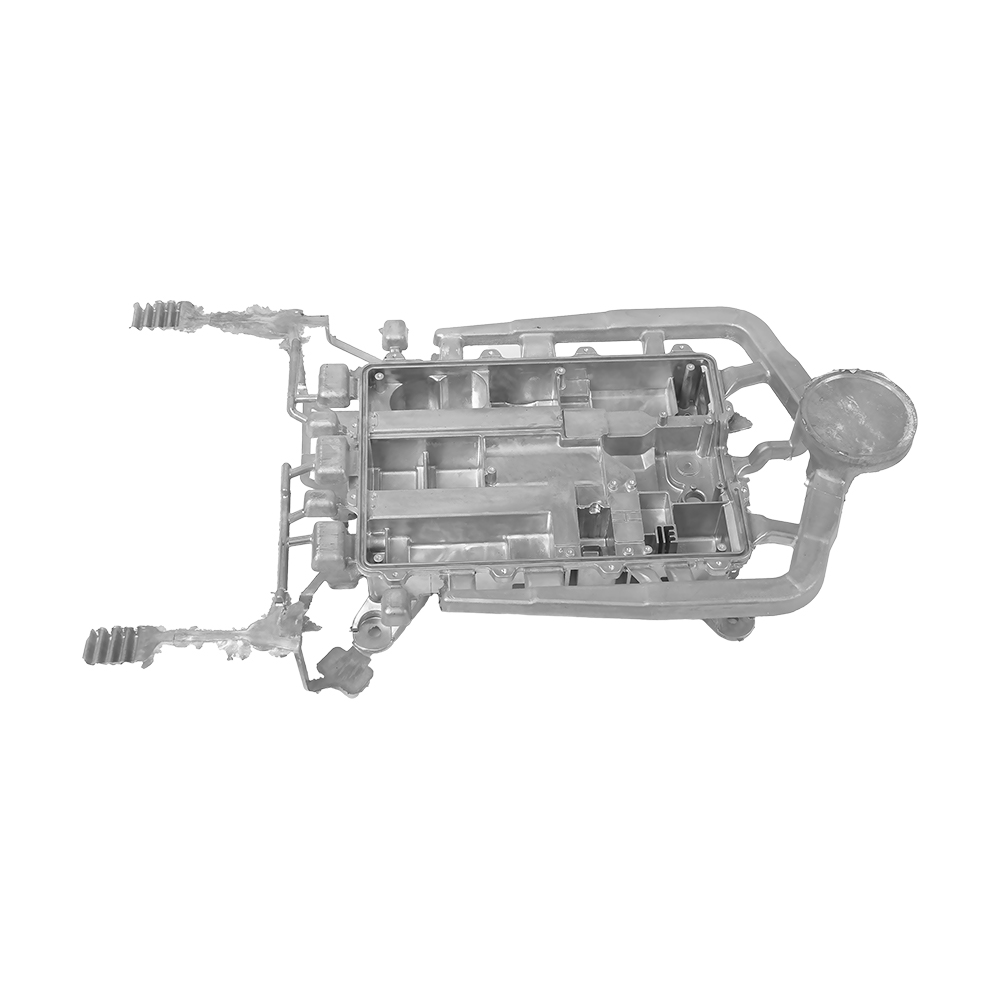

Aluminum Die Casting Gearbox Body

Cat:Aluminum Die Casting

High Precision: Utilizing precision aluminum alloy die-casting technology ensures the product's dime...

See Details -

Aluminum Bearing Bracket

Cat:Aluminum Die Casting

The Aluminum Bearing Bracket is a crucial mechanical component employed to support and secure bearin...

See Details -

Brushless Motor Accessories

Cat:Aluminum Die Casting

Our brushless motor accessories are crafted from high-quality metal materials, undergoing meticulous...

See Details -

Medical Device Accessories

Cat:Aluminum Die Casting

In the medical field, medical device accessories have a vital role in the normal operation and use t...

See Details -

Aluminum Plate

Cat:Aluminum Die Casting

Aluminum pressure casting is a kind of base assembly made of aluminum alloy material through pressur...

See Details -

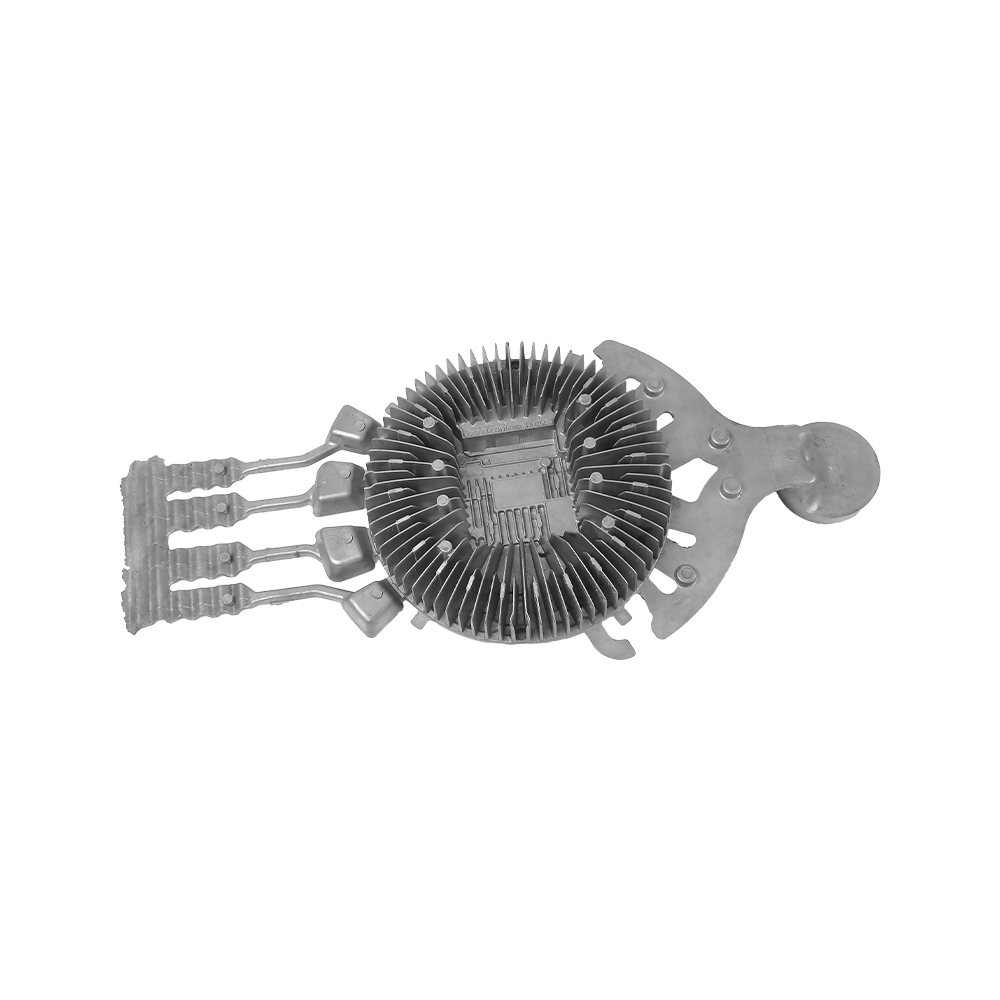

Fan Clutch

Cat:Aluminum Die Casting

The fan clutch is a device that controls the speed of the fan, usually used in automobiles and other...

See Details -

IR Valve Cover

Cat:Aluminum Die Casting

IR valve cover is a special valve door part, usually used to control the flow of medium in the pipe....

See Details

As a professional a China custom Rice Transplanter Spare Parts manufacturers and Rice Transplanter Spare Parts suppliers, The company currently has fixed assets of about 10 million die-casting, CNC and intelligent processing equipment, an annual output value of about 30 million. We have been indirectly supporting the production of aluminium products for well-known domestic enterprises for many years. There are Huawei base station lifting ground cylinders, Jiangsu radio factory military satellite phone aluminium parts, Nanjing Fuleiwei agricultural machinery rice transplanter parts, Beilun Top brushless car motor parts and so on.

-

Direct Answer: Is Die Casting Strong? Yes, die casting produces exceptionally strong parts that often exceed the strength of plastic injection molding and rival the structural integrity of some forge...

READ MORE -

Direct Answer: Is Die Cast Healthy and Safe? Generally speaking, products made through die casting are considered healthy and safe for everyday use, provided they meet international safety standards ...

READ MORE -

The Role of Permanent Molds in Die Casting Yes, die casting strictly utilizes permanent molds, which are typically crafted from high-strength heat-resistant steel. Unlike sand casting or investment c...

READ MORE

Can the use of rice transplanter spare parts help people complete large-scale transplanting operations?

Yes, the use of rice transplanter spare parts plays a crucial role in helping people complete large-scale transplanting operations. As one of the modern agricultural mechanization equipment, the design and function of rice transplanter are aimed at efficiently and accurately completing the transplanting operation. As an important component of the rice transplanter, the quality and performance of spare parts directly affect the overall operating efficiency and operational quality of the rice transplanter.

By using high-quality rice transplanter spare parts, stable performance and efficient operation of the transplanters can be ensured during operation. Spare parts such as seedling boxes, seedling sorting mechanisms, and seedling feeding mechanisms have been carefully designed and manufactured to meet the needs of large-scale and high-efficiency transplanting. These spare parts work together to enable the rice transplanter to complete transplanting operations continuously and quickly, greatly improving operational efficiency.

In addition, the use of spare parts can also reduce the failure rate and downtime of the rice transplanter during operation. High quality spare parts have better wear resistance, corrosion resistance, and fatigue resistance, and can operate stably for a long time in harsh field working environments. This reduces downtime caused by malfunctions, ensuring the continuity and efficiency of transplanting operations.

Therefore, it can be said that the use of rice transplanter spare parts is crucial in helping people complete large-scale transplanting operations. They not only improve work efficiency, but also ensure work quality and reduce production costs, making them indispensable and important equipment in modern agricultural production.

Can rice transplanter spare parts flexibly adapt to different terrain conditions?

Rice transplanter spare parts do have a certain degree of flexibility in adapting to different terrain conditions, but this flexibility is limited and mainly depends on the overall design and configuration of the transplanter, as well as the applicability and adjustability of spare parts.

Firstly, the design of rice transplanters usually takes into account certain terrain adaptability, including optimization of walking devices, transmission systems, suspension systems, and other aspects. However, this design is usually designed for a certain range of terrain conditions and cannot fully cover all possible terrains that may be encountered.

Secondly, as a component of the rice transplanter, spare parts will also be designed and manufactured with a certain degree of universality and replaceability in mind. For example, some spare parts may have different specifications and models to accommodate different brands and models of rice transplanters. Meanwhile, some spare parts (such as tires, tracks, etc.) may have different patterns and materials to provide better grip and anti-skid performance, thus adapting to different terrain conditions to a certain extent.

However, it should be noted that not all spare parts can flexibly adapt to all terrain conditions. For example, certain specially designed spare parts may only be suitable for flat fields, while they may not function properly in complex terrains such as slopes or wetlands. Therefore, when selecting spare parts, it is necessary to comprehensively consider the actual terrain conditions and operational requirements.

In addition, even if the spare parts themselves have a certain degree of adaptability, they still need to be matched with the overall design and configuration of the rice transplanter in order to achieve the best results. If the spare parts are incompatible or poorly coordinated with other parts of the rice transplanter, it may lead to performance degradation, increased failure rate, and other issues.

In summary, rice transplanter spare parts have a certain degree of flexibility in adapting to different terrain conditions, but this flexibility is limited and requires comprehensive consideration of the overall design, configuration, and applicability and adjustability of spare parts for the transplanter. In practical applications, it is necessary to select suitable spare parts based on specific terrain conditions and operational requirements, and make necessary adjustments and optimizations to ensure the normal and efficient operation of the rice transplanter.

Address Dalun Mould Venture Park, Beilun, Ningbo, Zhejiang, China

Tel +86 13586867000

E-mail cindy@youyuandiecasting.com

2021 © All Rights Reserved by Ningbo Beilun Youyuan Machinery Manufacturing Co., Ltd. Rice Transplanter Spare Parts manufacturers custom Rice Transplanter Spare Parts suppliers

English

English русский

русский Español

Español