Web Menu

Product Search

Exit Menu

Product Series

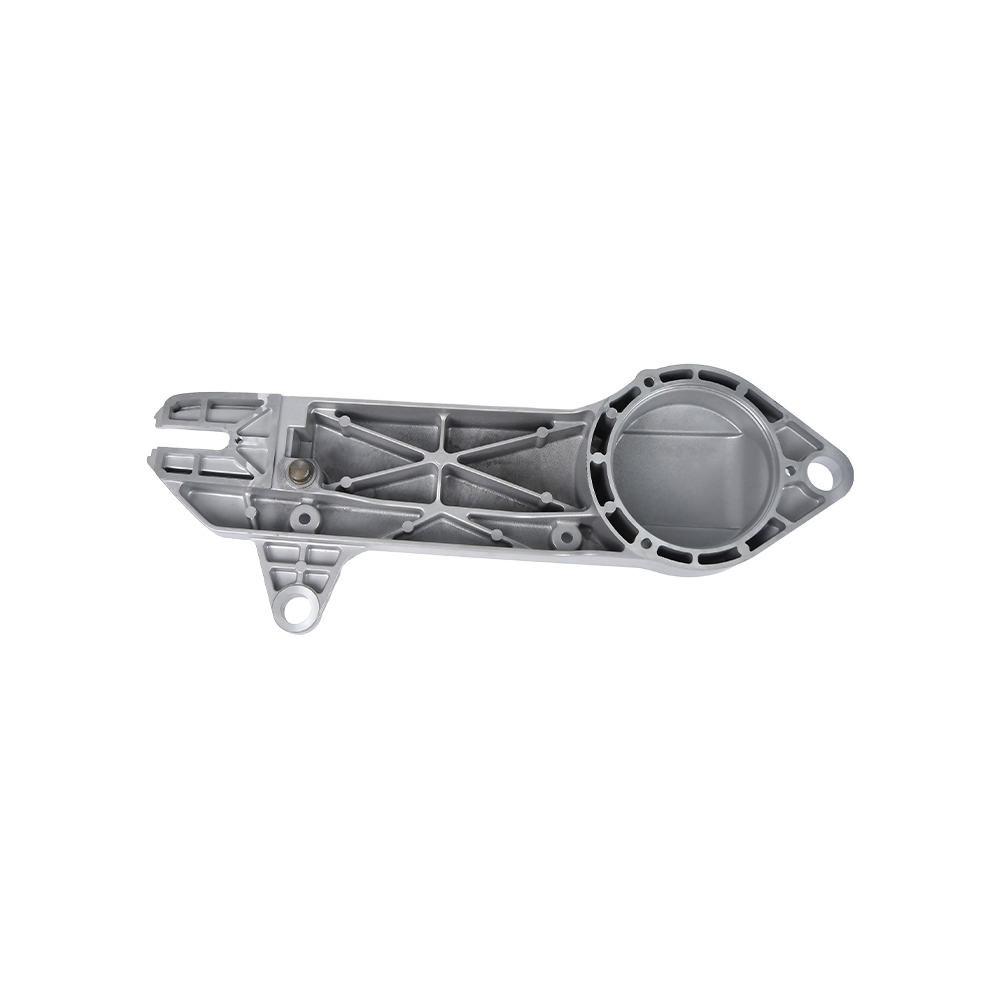

Aluminum Die Casting Motor Guard Plate

- Description

- Contact Us

Related Products

-

Aluminum Die Casting Gasoline Engine Case

Cat:Aluminum Die Casting

Aluminum die casting for gasoline engine cases is a sophisticated manufacturing process that plays a...

See Details -

Aluminum Cast Implantation Arm

Cat:Aluminum Die Casting

The utilization of aluminum cast implantation arms represents a cutting-edge development in the fiel...

See Details -

Aluminum Cast Engine Oil Pump

Cat:Aluminum Die Casting

This product is a high-quality aluminum alloy cast engine oil pump designed for various types of eng...

See Details -

Heat Dissipation Cover, End Cover

Cat:Aluminum Die Casting

These metal components are specifically designed to meet the high-temperature requirements of indust...

See Details -

Aluminum Auto Engine Cylinder Parts

Cat:Aluminum Die Casting

These components are specifically designed for modern automotive engines, providing performance and ...

See Details -

New Energy Vehicle Heat Dissipation Aluminum Substrate

Cat:Aluminum Die Casting

This new energy vehicle utilizes an aluminum alloy substrate for heat dissipation, employing high-qu...

See Details -

High Precision High Pressure Aluminum Die Casting Auto Parts

Cat:Aluminum Die Casting

High-precision high-pressure aluminum die-casting auto parts are an important component of automobil...

See Details -

Aluminum Die Cast Motor Housing 375

Cat:Aluminum Die Casting

Aluminum Die Cast Motor Housing 375 is a kind of metal shell used to protect the motor. Its main fun...

See Details -

Medical Device Accessories

Cat:Aluminum Die Casting

In the medical field, medical device accessories have a vital role in the normal operation and use t...

See Details -

Automobile Cylinder Body Parts

Cat:Low Pressure Die Casting

Automobile cylinder body parts are an important part of the automobile engine, whose function is to ...

See Details

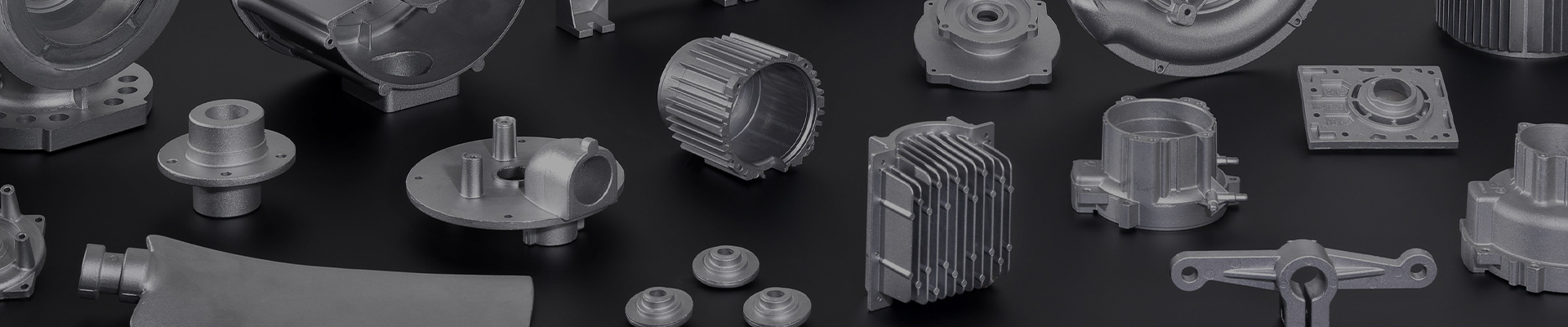

As a professional a China custom Aluminum Die Casting Motor Guard Plate manufacturers and Aluminum Die Casting Motor Guard Plate suppliers, The company currently has fixed assets of about 10 million die-casting, CNC and intelligent processing equipment, an annual output value of about 30 million. We have been indirectly supporting the production of aluminium products for well-known domestic enterprises for many years. There are Huawei base station lifting ground cylinders, Jiangsu radio factory military satellite phone aluminium parts, Nanjing Fuleiwei agricultural machinery rice transplanter parts, Beilun Top brushless car motor parts and so on.

-

Die-cast parts are practically everywhere in our lives. Just look around, and you'll find that many of the cool-to-the-touch, intricately shaped, and sturdy metal objects are made using this process. ...

READ MORE -

Die casting is like making "metal ice cubes" or "high-end injection molding." It's a process where molten metal is "forced" under high pressure into a precision mold, then cooled to form solid parts. ...

READ MORE -

In the world of die casting, there are two main categories based on how the metal is melted and injected into the mold: hot chamber die casting and cold chamber die casting.You can think of them as th...

READ MORE

Can the aluminum die casting motor guard plate protect the motor from water in a rainy environment?

The aluminum die-casting motor guard plate can protect the motor to some extent from water ingress in rainy environments, but its waterproof effect depends on multiple factors.

Firstly, the design of aluminum die-casting motor guard plates usually considers waterproof performance, including the shape of the guard plates, sealing structure, and installation position. If the guard plates is designed reasonably and installed with good sealing, it can effectively block rainwater from directly contacting the motor.

However, it should be noted that there are no absolute waterproof measures. In some extreme cases, such as rainstorm, flood or vehicle wading, rainwater may penetrate into the motor through the gap between the guard plate and the motor, ventilation holes or other unsealed openings. In addition, if there are defects or damages in the guard plates itself, such as cracks, deformation, or aging of the sealing gasket, it can also lead to a decrease in waterproof performance.

Therefore, although aluminum die-casting motor guard plates can provide some waterproof protection, other measures still need to be taken to ensure the safety of the motor in rainy environments. For example, the integrity and sealing of the guard plates can be checked regularly, and damaged components can be repaired or replaced in a timely manner; In extreme weather conditions, additional waterproof covers or other waterproof measures can be considered to enhance protection; At the same time, keep the drainage system at the bottom of the vehicle unobstructed to promptly drain accumulated water and reduce the potential threat of rainwater to the motor.

In summary, aluminum die-casting motor guard plates can to some extent protect the motor from water ingress, but in practical use, attention should still be paid to the completeness and effectiveness of waterproof measures.

Can the aluminum die casting motor guard plate be installed on the heat dissipation holes or vents of the motor?

Aluminum die-casting motor guard plates are usually not recommended to be installed on the heat dissipation holes or ventilation openings of the motor. The following is a detailed analysis of this issue:

1、 The importance of heat dissipation holes and ventilation openings

Heat dissipation function: The heat dissipation holes and ventilation openings of the motor are key parts to ensure the normal operation of the motor. They allow air circulation and help the motor dissipate the heat generated during operation, thereby preventing the motor from overheating.

Ventilation efficiency: If the guard plate is installed on the heat dissipation holes or ventilation openings, it will hinder the free flow of air, resulting in a decrease in the ventilation efficiency of the motor. This not only affects the heat dissipation effect of the motor, but may also increase the risk of motor overheating, thereby affecting its performance and lifespan.

2、 Precautions for installing guard plates

Avoid obstruction: When installing the aluminum die-casting motor guard plate, ensure that it does not obstruct the motor's heat dissipation holes and ventilation openings. The design of the guard plate should fully consider the heat dissipation requirements of the motor to ensure smooth air circulation.

Maintain appropriate clearance: If the guard plate needs to be installed around the motor to provide protection, it is recommended to maintain an appropriate clearance with the surface of the motor. This ensures that the air can circulate freely and take away the heat generated by the motor.

Choosing appropriate materials: When selecting guard plate materials, in addition to considering their strength and corrosion resistance, their heat dissipation performance should also be taken into account. Choosing materials with good thermal conductivity can improve the heat dissipation efficiency of the motor to a certain extent.

3、 Conclusion

In summary, it is not recommended to install aluminum die-casting motor guard plates on the heat dissipation holes or ventilation openings of the motor. In order to ensure the normal operation of the motor and extend its service life, it is necessary to ensure that the heat dissipation holes and ventilation openings are unobstructed, and corresponding heat dissipation measures should be taken to improve the heat dissipation efficiency of the motor. When installing the guard plate, it is necessary to follow the relevant installation specifications and recommendations to ensure that it will not have a negative impact on the heat dissipation performance of the motor.

4、 Suggestion

If a guard plate needs to be installed around the motor to provide protection, it is recommended to consult a professional motor manufacturer or technician for more specific installation guidance and advice. They can provide you with the most suitable solution based on the specific model and working environment of the motor.

Address Dalun Mould Venture Park, Beilun, Ningbo, Zhejiang, China

Tel +86 13586867000

E-mail cindy@youyuandiecasting.com

2021 © All Rights Reserved by Ningbo Beilun Youyuan Machinery Manufacturing Co., Ltd. Aluminum Die Casting Motor Guard Plate manufacturers custom Aluminum Die Casting Motor Guard Plate suppliers

English

English русский

русский Español

Español