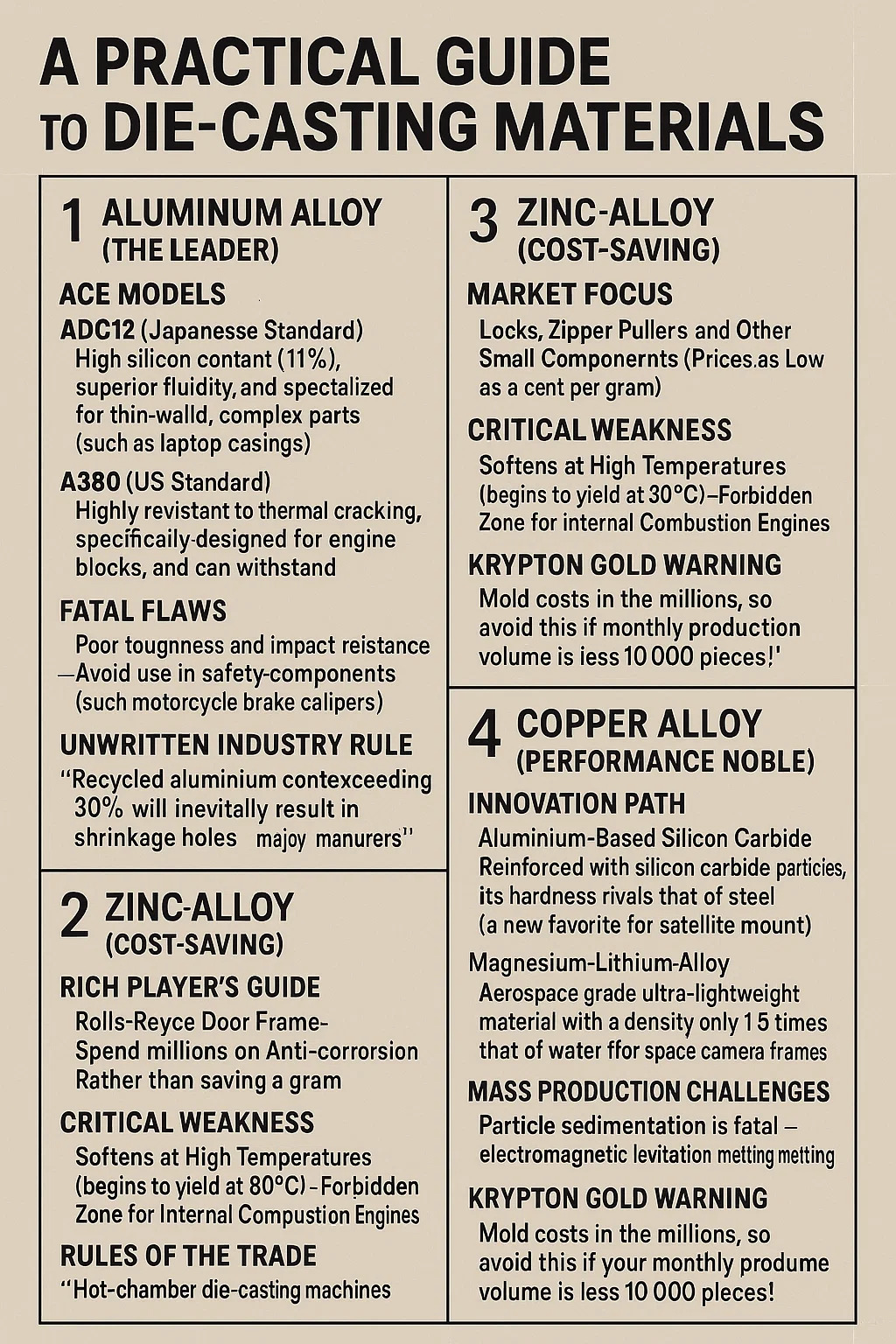

A Practical Guide to Die-Casting Materials

Content

1. Aluminum Alloy (The Leader)

Ace Model:

ADC12 (Japanese Standard): High silicon content (11%), superior fluidity, and specialized for thin-walled, complex parts (such as laptop casings).

A380 (US Standard): Highly resistant to thermal cracking, specifically designed for engine blocks, and can withstand temperatures exceeding 200°C.

Fatal Flaws:

Poor toughness and impact resistance—avoid use in safety components (such as motorcycle brake calipers).

Unwritten Industry Rule:

"Recycled aluminum content exceeding 30% will inevitably result in shrinkage holes—major manufacturers strictly control waste sources!"

2. Magnesium Alloy (The Lightweight Assassin)

Performance Highlights:

33% lighter than aluminum, the highest specific strength (used in fighter jet instrument panels).

Unrivaled electromagnetic shielding (used in military radar casings and nuclear weapons).

Critical Flaws:

Instant corrosion from moisture—requires argon atmosphere for melting.

Flash point of only 450°C—no water or oil allowed at the die-casting site. Rich Player's Guide:

Rolls-Royce Door Frame - Spend Millions on Anti-Corrosion Rather Than Save a Gram

3. Zinc Alloy (Cost-Saving)

Market Focus:

Locks, Zipper Pullers, and Other Small Components (Prices as Low as a Cent per Gram).

Surface Electroplating Adhesion Superior to Aluminum and Magnesium (Top-Rated Bathroom Faucets).

Critical Weakness:

Softens at High Temperatures (Begins to Yield at 80°C) - Forbidden Zone for Internal Combustion Engines.

Acid- and Alkali-Averse - Chrome Plating is Required for Outdoor Parts.

Rules of the Trade:

"Hot-chamber die-casting machines are the only true king of zinc alloys - Cold-chamber die-casting machines will cause cylinder blockage and machine failure!"

4. Copper Alloy (Performance Noble)

God-Level Attributes:

Double-Above-Rated Electrical and Thermal Conductivity (Must-Have for High-Voltage Circuit Breaker Contacts).

Corrosion Resistance Sweeps Marine and Chemical Industries (Dominant for Ship Valves).

Discouragement:

Melting Point 1083°C - Steel Die Life Only 1/10th of that of Aluminum Die-casting Machines. Density three times that of aluminum—die-casting machines require a thousand-ton minimum.

Krypton Gold Warning:

Mold costs in the millions, so avoid this if your monthly production volume is less than 10,000 pieces!

5. Composite Materials (Future Dark Horse)

Innovation Path:

Aluminum-Based Silicon Carbide: Reinforced with silicon carbide particles, its hardness rivals that of steel (a new favorite for satellite mounts).

Magnesium-Lithium Alloy: Aerospace-grade ultra-lightweight material with a density only 1.5 times that of water (for space camera frames).

Mass Production Challenges:

Particle sedimentation is fatal—electromagnetic levitation melting is required.

≤ 3 stable global suppliers.

English

English русский

русский Español

Español