About Us

Ningbo Beilun Youyuan Machinery Manufacturing Co., Ltd.

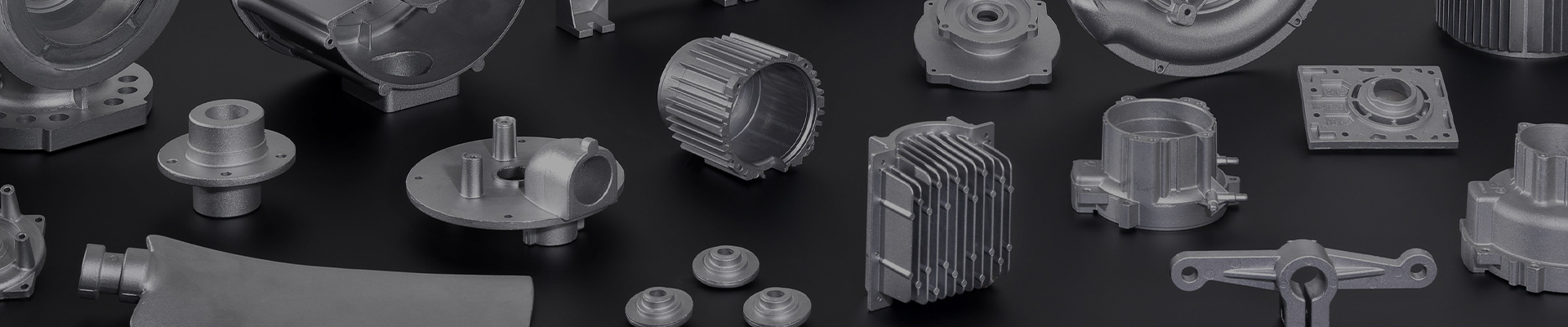

Ningbo Beilun Youyuan Machinery Manufacturing Co., Ltd. was founded in 2010 and is a high-tech enterprise focusing on aluminium product moulds, die-casting, and machining production in one. Since its inception, the company has always adhered to people-oriented, integrity-based business principles, and actively improved the management level and production capacity of enterprises, so that enterprises in the fierce market competition to achieve rapid and stable development.

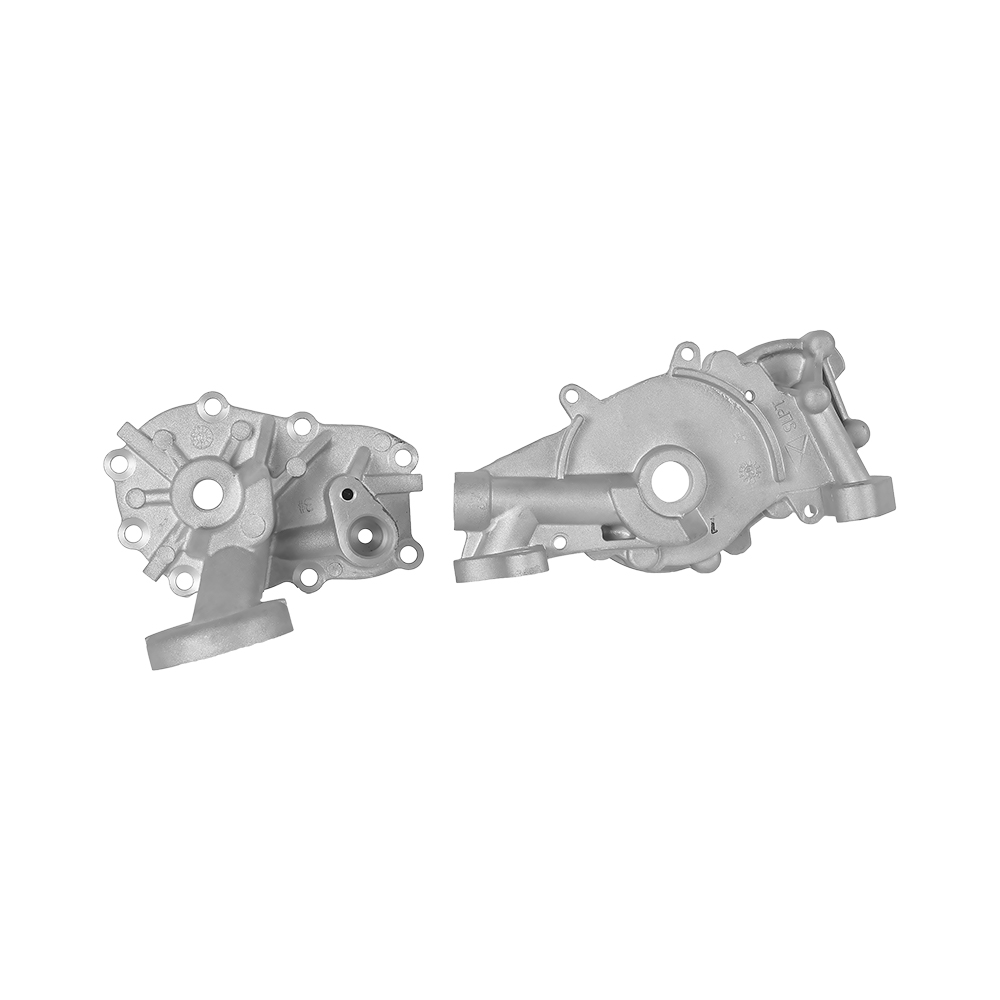

As a professional a China custom Automobile Engine Water Pump manufacturers and Automobile Engine Water Pump suppliers, The company currently has fixed assets of about 10 million die-casting, CNC and intelligent processing equipment, an annual output value of about 30 million. We have been indirectly supporting the production of aluminium products for well-known domestic enterprises for many years. There are Huawei base station lifting ground cylinders, Jiangsu radio factory military satellite phone aluminium parts, Nanjing Fuleiwei agricultural machinery rice transplanter parts, Beilun Top brushless car motor parts and so on.

As a professional a China custom Automobile Engine Water Pump manufacturers and Automobile Engine Water Pump suppliers, The company currently has fixed assets of about 10 million die-casting, CNC and intelligent processing equipment, an annual output value of about 30 million. We have been indirectly supporting the production of aluminium products for well-known domestic enterprises for many years. There are Huawei base station lifting ground cylinders, Jiangsu radio factory military satellite phone aluminium parts, Nanjing Fuleiwei agricultural machinery rice transplanter parts, Beilun Top brushless car motor parts and so on.

Certificate Of Honor

News

-

The main advantage of die casting is its ability to produce large volumes of complex, dimensionally accurate metal parts at high speed with minimal post-processing. In a single production cycle, die ...

READ MORE -

Direct Answer: Is Die Casting Strong? Yes, die casting produces exceptionally strong parts that often exceed the strength of plastic injection molding and rival the structural integrity of some forge...

READ MORE -

Direct Answer: Is Die Cast Healthy and Safe? Generally speaking, products made through die casting are considered healthy and safe for everyday use, provided they meet international safety standards ...

READ MORE

Message Feedback

English

English русский

русский Español

Español