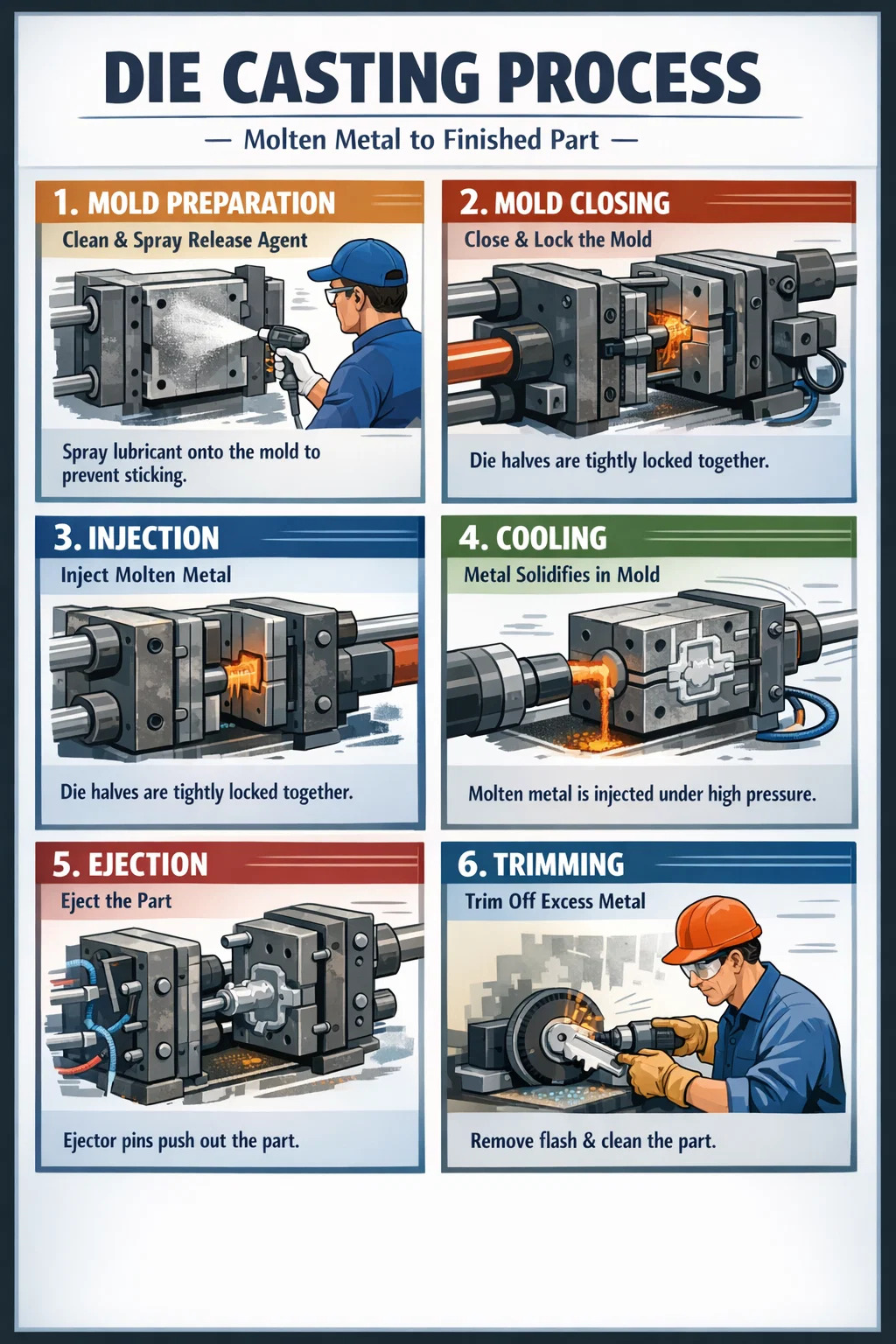

Die casting is like making "metal ice cubes" or "high-end injection molding." It's a process where molten metal is "forced" under high pressure into a precision mold, then cooled to form solid parts.

Content

1. Preparing the Mold (Cleaning and Spraying)

Before starting, the technician cleans the metal mold and then sprays a release agent onto the mold surface.

Why this is done: This is like greasing a pan before frying an egg, preventing the molten metal from sticking to the mold and making it difficult to remove. It also helps cool the mold and protect it from being damaged by the heat.

2. Closing and Locking the Die

Two heavy steel molds are tightly closed together.

Key point: At this point, the machine applies immense force to lock the mold. Because the pressure is very high, if the mold isn't locked tightly, the molten metal will spray out from the gaps, and the part will be ruined.

3. Injecting the Molten Metal (Injection)

This step is the core of die casting. The molten metal is poured into the machine's inlet.

High-pressure injection: A piston (plunger) in the machine acts like a syringe, forcefully injecting the molten metal into the mold in a very short time. This action must be fast, otherwise the metal will cool down midway, resulting in an incomplete part.

4. Cooling and Shaping (Cooling)

After the metal enters the mold, the heat dissipates quickly because the mold itself has a cooling system.

Solidification: The liquid metal solidifies within a few seconds to tens of seconds (depending on the size of the part), turning back into a hard solid.

5. Opening the Mold and Removing the Part (Ejection)

After the metal has completely hardened, the machine automatically opens the mold.

Ejecting the part: Ejector pins in the mold push out the finished part. The part is still hot at this point, and is usually picked up by a robotic arm or conveyor belt.

6. Trimming and Finishing (Trimming)

The newly produced part is not perfect; its edges usually have some excess metal scraps (called "flash" or "gate"). Deburring: Workers use presses or grinding machines to cut off the excess material, leaving only the clean, finished product. The discarded scraps are not wasted; they can be melted down in a furnace and reused.

English

English русский

русский Español

Español