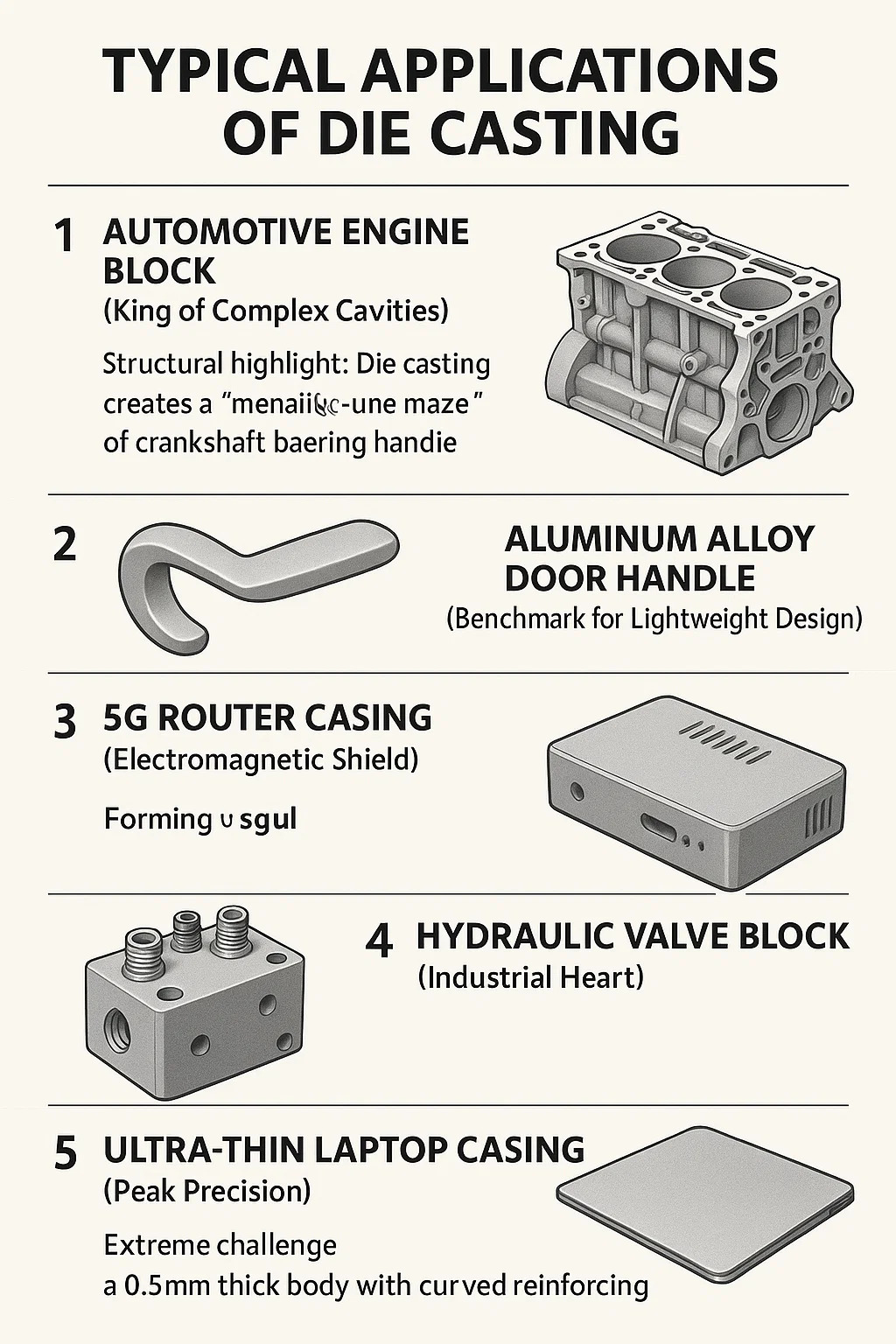

Typical Applications of Die Casting:

1. Automotive Engine Block (King of Complex Cavities)

Structural Highlights: Die casting creates a "three-in-one maze" of crankshaft bearing housings, cooling water channels, and oil passages in a single process, much like casting a network of interconnected metal tunnels within a steel mold.

Irreplaceable Advantages: Traditionally welded cooling water channels are prone to antifreeze leaks; die-cast cylinder blocks are seamless and leak-proof for life.

2. Aluminum Alloy Door Handles (Benchmark for Lightweight Design)

Craftsmanship Essence: Zinc alloy is melted into a "metallic soup," then high-pressure injected into a sculpted steel mold, creating a curved handle with fingerprint-like texture in 3 seconds. It weighs 60% less than stainless steel.

User Value: Comfortable to the touch in winter, rust-free for ten years after electroplating, and 70% cheaper than CNC machining.

3. 5G Router Casing (Electromagnetic Shield)

Key Technology: Molten aluminum encases a metal shielding layer within a mold, forming a signal isolation chamber. The antenna window and heat dissipation holes are cast in one piece, eliminating signal leakage through assembly gaps.

Effect Comparison: Traditional plastic casings require copper foil—easily detached and causing signal attenuation; die-cast aluminum casings provide full signal strength without lag.

4. Hydraulic Valve Block (Industrial Heart)

Core Advantage: Intersecting oil passages are die-cast within a steel block, like "digging a tunnel" inside metal, withstanding 500 kg of pressure without cracking or leaking.

Traditional Pain Points: Drilled oil passages are prone to stress cracking at corners; die-cast channels are smooth and without dead angles.

5. Ultra-Thin Laptop Casing (Peak Precision)

Extreme Challenge: A 0.5mm thick body with curved reinforcing ribs is die-cast from magnesium alloy, weighing comparable to plastic while possessing sufficient strength to withstand pressure.

Process threshold: Deformation will occur if the temperature difference of the mold exceeds 5℃, and precise temperature control is required to maintain the dimensions.

English

English русский

русский Español

Español