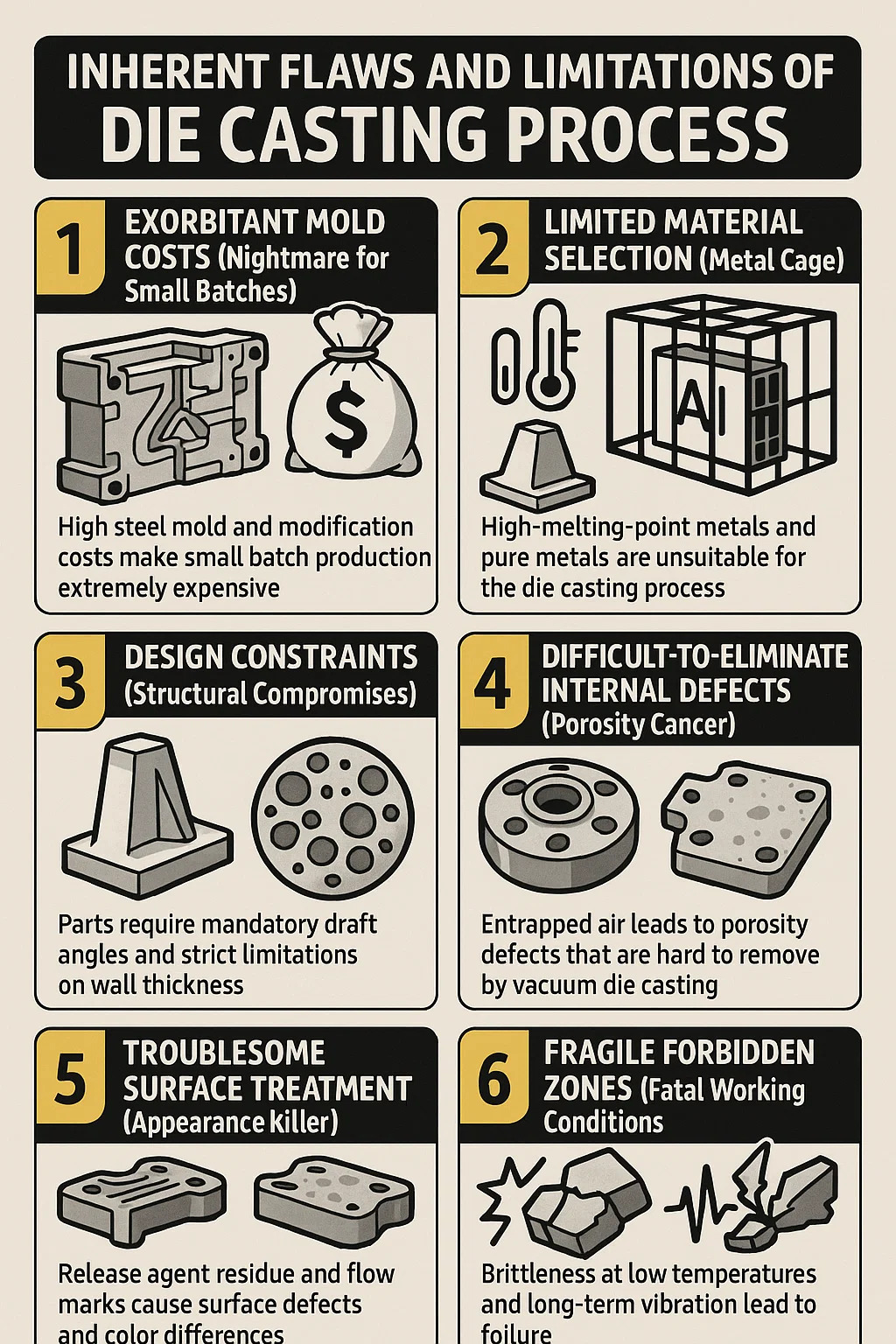

Inherent Flaws and Limitations of Die Casting Process

Content

- 1 1. Exorbitant Mold Costs (Nightmare for Small Batches)

- 2 2. Limited Material Selection (Metal Cage)

- 3 3. Design Constraints (Structural Compromises)

- 4 4. Difficult-to-Eliminate Internal Defects (Porosity Cancer)

- 5 5. Troublesome Surface Treatment (Appearance Killer)

- 6 6. Fragile Forbidden Zones (Fatal Working Conditions)

1. Exorbitant Mold Costs (Nightmare for Small Batches)

High steel mold cost: Engraving a die casting mold costs hundreds of thousands of dollars, and complex structures (such as automotive cylinder block molds) can cost as much as a luxury car.

High cost of trial and error: If there are defects in the mold design, the cost of a single modification is enough to buy ten iPhones; small businesses simply cannot afford it.

2. Limited Material Selection (Metal Cage)

Fear of high-melting-point metals: Copper, steel, and other metals require ultra-high temperatures to melt, directly burning out the mold; only "soft" metals like aluminum, zinc, and magnesium can be used.

Avoidance of pure metals: Pure aluminum has poor fluidity and must be mixed with silicon/copper to form an alloy, forcing a compromise in performance.

3. Design Constraints (Structural Compromises)

Mandatory draft angle compromise: Parts must have a draft angle of ≥1° (like a pyramid shape); straight up and down structures will stick to the mold and be scrapped.

Wall thickness limitations: Too thin (<0.5mm) prevents complete filling with molten aluminum, and too thick (>15mm) inevitably produces shrinkage cavities; designers are forced to meticulously calculate every millimeter.

4. Difficult-to-Eliminate Internal Defects (Porosity Cancer)

Entrapped air: Air is trapped during high-speed injection, resulting in bubbles (porosity) inside the part, appearing like honeycomb coal under X-ray.

Vacuum die casting is also difficult to cure: Although it can reduce porosity, the equipment is 30% more expensive, making it unaffordable for small factories.

5. Troublesome Surface Treatment (Appearance Killer)

Release agent residue: If the water-based release agent is not completely blown off, white spots will appear on the surface of the part, resembling mold after anodizing.

Flow marks and color differences: The flow marks of the molten aluminum cannot be completely eliminated, showing "water ripples" when painted with light colors.

6. Fragile Forbidden Zones (Fatal Working Conditions)

Brittleness at ultra-low temperatures: Below -30℃, aluminum alloys become "cookies," shattering upon impact (e.g., equipment parts used in the Arctic).

Long-term vibration leads to fatigue: Micro-pores inside die-cast parts expand under vibration, eventually leading to fracture (e.g., engine mounting brackets).

English

English русский

русский Español

Español