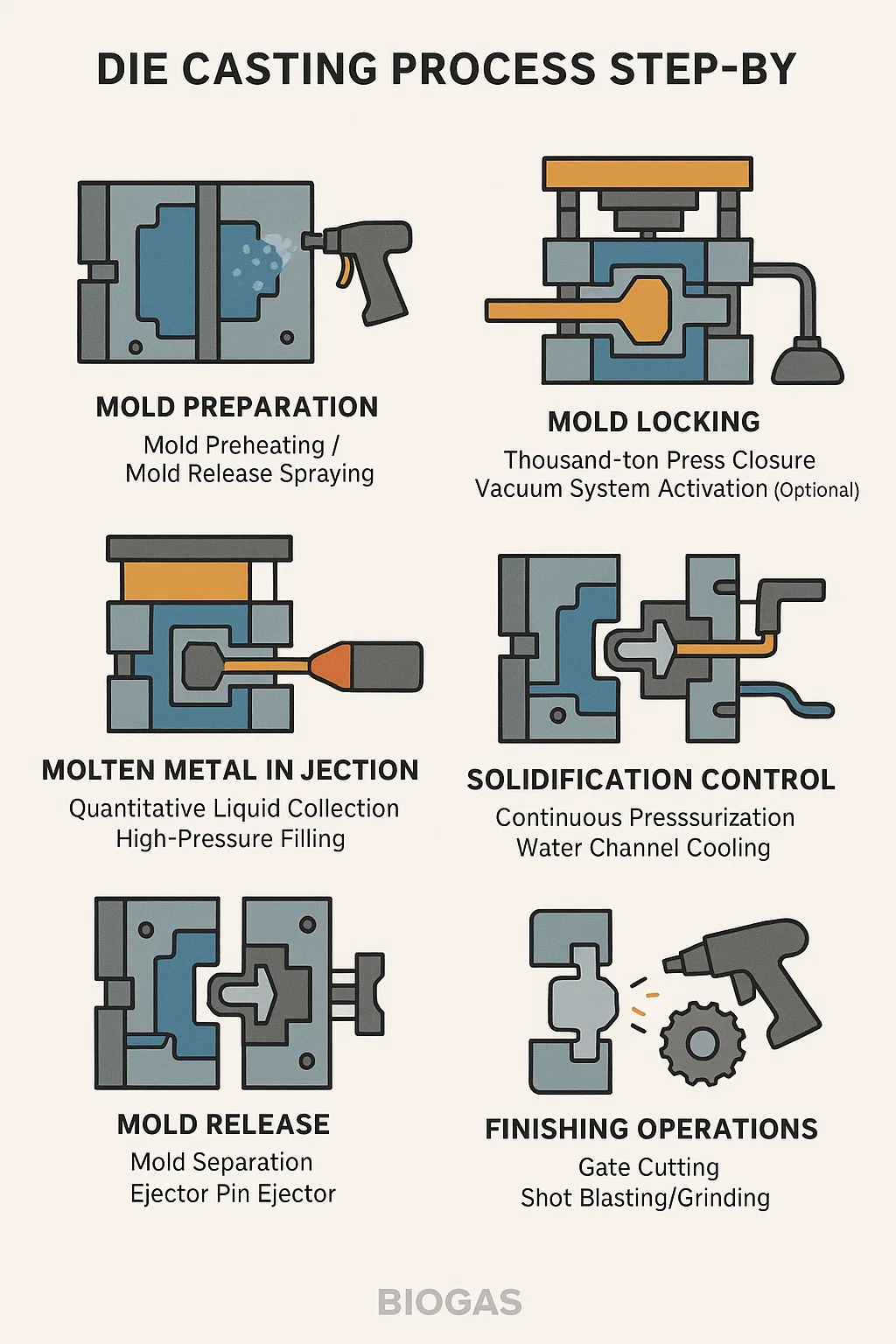

Die Casting Process Step-by-Step

1. Mold Preparation (Core Step)

Mold Preheating: Heat the steel mold to 150-200°C to prevent molten aluminum from splashing or cold shutting.

Mold Release Spraying: Use an air mist gun to evenly spray the cavity (water-based emulsion) to protect the mold and aid demolding.

2. Mold Locking (Critical Safety)

Thousand-ton Press Closure: The upper and lower molds are hydraulically locked to withstand the high injection pressure (>500 tons clamping force).

Vacuum System Activation (Optional): Evacuate air from the mold cavity to reduce air porosity.

3. Molten Metal Injection (High-Velocity Injection)

Quantitative Liquid Collection: Molten aluminum (approximately 660°C) is automatically ladle-fed into the injection chamber from the furnace.

High-Pressure Filling: A plunger injects molten aluminum into the mold cavity at cannonball speed (30-100 m/s), filling the cavity within 0.01-0.3 seconds.

4. Solidification Control

Continuous Pressurization: The plunger maintains high pressure for 10-30 seconds to compensate for the shrinkage of the molten aluminum during solidification.

Water Channel Cooling: Cold water circulates within the mold to remove heat, allowing the part to solidify quickly.

5. Mold Release

Mold Separation: The press is released, and the upper and lower molds open.

Ejector Pin Ejector: A built-in ejector pin ejects the part, removing runner waste (approximately 30% of the material).

6. Finishing Operations

Gate Cutting: Hydraulic shearing removes the gating system and overflow trough.

Shot Blasting/Grinding: Removes burrs and parting line flash.

Heat Treatment (Key Components): T6 hardening increases hardness.

English

English русский

русский Español

Español