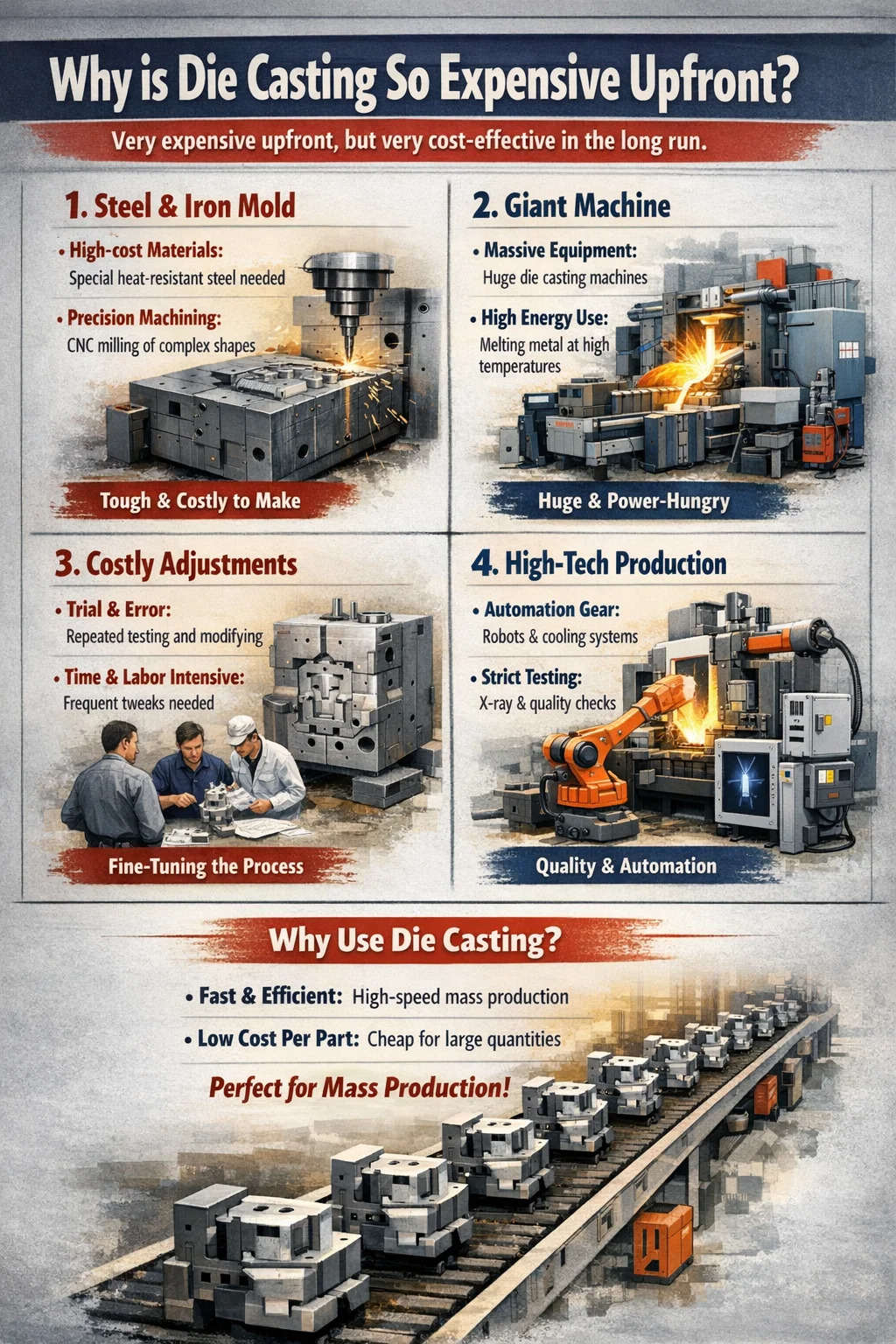

Many people, when first encountering die casting, often react with: "This part doesn't look complicated, why is making a mold so expensive?"

In fact, die casting is indeed a process that is "very expensive upfront, but very cost-effective in the long run." Its high cost is mainly reflected in the initial investment. We can break down this process:

Content

1. The mold is made of "steel and iron"

Die casting molds are not ordinary molds. Because molten metal at several hundred or even a thousand degrees Celsius needs to be injected into them, and immense pressure is required to "force" the metal in.

Expensive materials: These molds must be made of very expensive special heat-resistant steel; otherwise, they will deform or crack after only a few uses.

Difficult processing: Creating complex shapes in such hard steel requires precision CNC machines to mill them out bit by bit, which is time-consuming and labor-intensive.

2. The machine is a "giant"

The die casting machine itself is a large, heavy piece of equipment, with a clamping force of hundreds or even thousands of tons.

High equipment costs: Purchasing, installing, and maintaining these behemoths requires a huge investment.

High energy consumption: Maintaining the molten metal requires a large amount of electricity or gas, and the power consumption during machine operation is also considerable.

3. The cost of "meticulous" trial and error

After a new product's die casting mold is made, it cannot be immediately used for mass production.

Repeated adjustments: Engineers need to constantly adjust the speed, pressure, and cooling time of the metal flow. If the resulting parts have pores or cracks, the mold may need to be modified again. This repeated adjustment process incurs very high labor and time costs.

4. High-demand production environment

To ensure the stable quality and high precision of die-cast parts, factories need to be equipped with expensive auxiliary equipment.

Automation investment: For example, robotic arms for part removal, automatic mold release agent spraying devices, and expensive mold cooling systems.

Rigorous testing: Every batch of parts may need to undergo precise testing such as X-ray flaw detection, and the operating costs of these devices are ultimately passed on to the product.

● Why are people still willing to use it?

Although die casting has an astonishing initial investment, it has a secret weapon: speed. Once the mold and machine are set up, a part can be produced in just a few seconds. If you need to produce tens of thousands or hundreds of thousands of units, the cost per part will actually be cheaper than with other manufacturing processes.

This is why it's suitable for mass production, but not for making just a few samples.

English

English русский

русский Español

Español