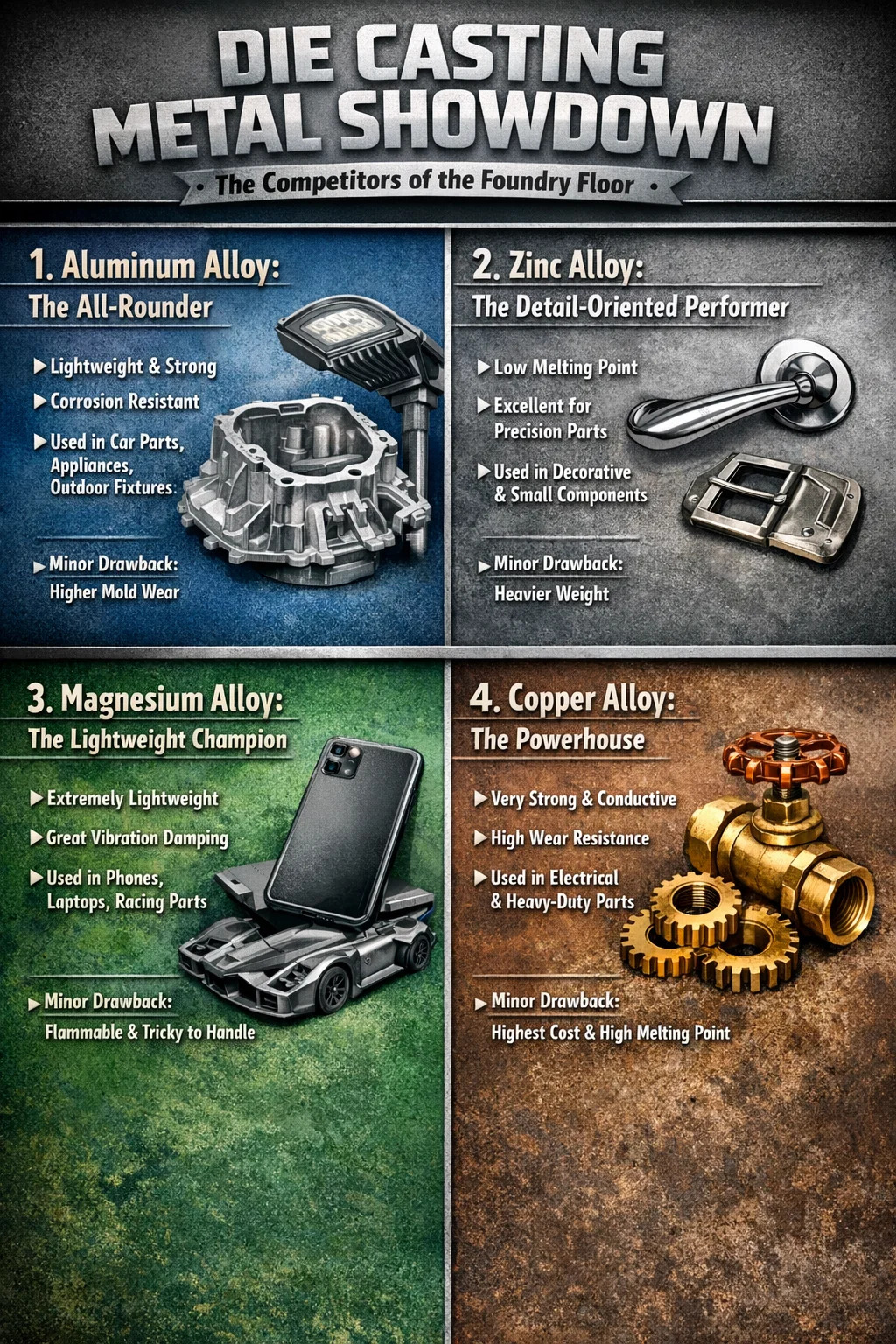

When it comes to which metal is best suited for die casting, there's no absolute "number one," as it depends on what you want to use it for. In factories, the three most commonly used metals are aluminum, zinc, and magnesium.

We can think of them as "competitors" with different characteristics, each excelling in different areas:

Content

1. Aluminum Alloy: The All-Rounder (Most Popular)

In the die casting field, aluminum alloy is definitely the "big brother."

▪ Why it's good: It's very lightweight, yet has excellent strength. Most importantly, it doesn't rust and can withstand high operating temperatures.

▪ Where it's used: It's the preferred choice for automotive parts, appliance casings, and outdoor lighting fixtures. For example, car engine casings need to be lightweight and dissipate heat quickly, making aluminum alloy the ideal choice.

▪ Minor drawback: Aluminum has a relatively high melting point, which causes slightly more wear and tear on the molds compared to zinc.

2. Zinc Alloy: The Detail-Oriented Performer (Most Mold-Friendly)

If you're looking for parts that are "beautiful" and have very precise dimensions, then zinc alloy is the right choice for die casting.

▪ Why it's good: Zinc has a very low melting point, like "quickly melting" chocolate, allowing it to easily flow into the smallest crevices of the mold. Because of its low melting point, it's very gentle on the molds, and a single mold can be used for a long time without breaking. It's also very easy to electroplate, resulting in shiny, high-quality products.

▪ Where it's used: Beautiful door handles, exquisite belt buckles, locks, and various small electronic parts that require a refined appearance.

▪ Minor drawback: Zinc is relatively heavy, so if your product is particularly sensitive to weight, it might not be the best option.

3. Magnesium Alloy: The Lightweight Champion (The Lightest Performer)

If you think aluminum isn't light enough, then the ultimate solution for die casting is magnesium alloy.

▪ Why it's good: It's currently the lightest structural metal material used in industrial applications. Despite being lightweight, it has excellent vibration damping capabilities.

▪ Where it's used: For "ultra-lightweight" mobile phone frames, laptop casings, and parts for high-end racing cars. ▪Minor drawback: Magnesium is quite "temperamental" during processing and is prone to catching fire, so factories require more professional safety precautions during production.

4. Copper Alloy: The Powerhouse (The most robust)

Although not as commonly used as the previous three, copper die casting is used in some special applications.

▪Why it's good: Copper is very hard, has excellent electrical conductivity, and its wear resistance is top-notch.

▪Where it's used: Primarily used in high-performance electrical components, water pipe valves, or heavy-duty parts requiring wear resistance.

▪Minor drawback: Copper has an extremely high melting point, posing significant challenges for die-casting machines and molds, resulting in the highest cost.

English

English русский

русский Español

Español