Web Menu

Product Search

Exit Menu

Product Series

Aluminum Auto Bearing Bracket

- Description

- Contact Us

Related Products

-

Aluminum Gear Reducer

Cat:Aluminum Die Casting

The aluminum gear reducer is a crucial component in various mechanical systems, renowned for its dur...

See Details -

Aluminum Die Casting Gasoline Engine Case

Cat:Aluminum Die Casting

Aluminum die casting for gasoline engine cases is a sophisticated manufacturing process that plays a...

See Details -

Galvanized Hydraulic Valve Block

Cat:Aluminum Die Casting

Galvanized hydraulic valve block is a kind of valve block that has been galvanized to prevent corros...

See Details -

Aluminum Cast Engine Oil Pump

Cat:Aluminum Die Casting

This product is a high-quality aluminum alloy cast engine oil pump designed for various types of eng...

See Details -

Aluminum Cast Engine Water Pump

Cat:Aluminum Die Casting

Our aluminum alloy cast engine water pump is crafted from high-quality aluminum alloy material, unde...

See Details -

Brushless Motor Accessories

Cat:Aluminum Die Casting

Our brushless motor accessories are crafted from high-quality metal materials, undergoing meticulous...

See Details -

Aluminum Casting Accessories Aluminum End Cap

Cat:Aluminum Die Casting

This Aluminum Casting Accessory, the Aluminum End Cap, is crafted from high-quality aluminum alloy m...

See Details -

High Precision High Pressure Aluminum Die Casting Auto Parts

Cat:Aluminum Die Casting

High-precision high-pressure aluminum die-casting auto parts are an important component of automobil...

See Details -

Aluminum Plate

Cat:Aluminum Die Casting

Aluminum pressure casting is a kind of base assembly made of aluminum alloy material through pressur...

See Details -

VP Valve Cover

Cat:Aluminum Die Casting

VP valve is a kind of valve door part, usually used to control the flow of medium in the pipe. It is...

See Details

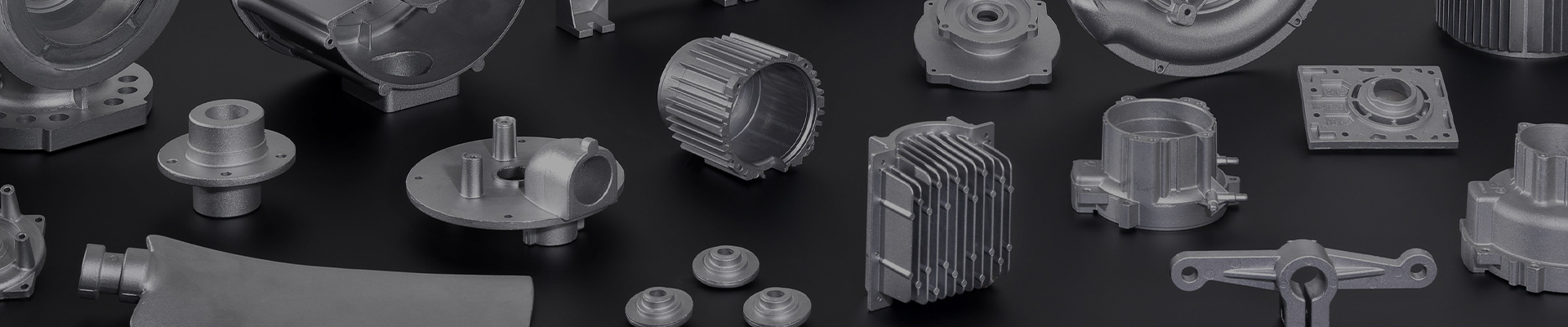

As a professional a China custom Aluminum Auto Bearing Bracket manufacturers and Aluminum Auto Bearing Bracket suppliers, The company currently has fixed assets of about 10 million die-casting, CNC and intelligent processing equipment, an annual output value of about 30 million. We have been indirectly supporting the production of aluminium products for well-known domestic enterprises for many years. There are Huawei base station lifting ground cylinders, Jiangsu radio factory military satellite phone aluminium parts, Nanjing Fuleiwei agricultural machinery rice transplanter parts, Beilun Top brushless car motor parts and so on.

-

The Role of Permanent Molds in Die Casting Yes, die casting strictly utilizes permanent molds, which are typically crafted from high-strength heat-resistant steel. Unlike sand casting or investment c...

READ MORE -

Regarding whether die casting or CNC machining is cheaper, the answer actually depends on how many parts you plan to produce.It's like printing flyers: if you only need one, handwriting is the cheapes...

READ MORE -

Many people might find the term "die cast" a little strange when they hear it for the first time: doesn't "die" mean "death" in English? In fact, in industrial manufacturing, this word has a completel...

READ MORE

Can the use of aluminum auto bearing bracket improve ride comfort?

The use of aluminum auto bearing brackets, although not directly determining all aspects of ride comfort, can indirectly improve ride comfort. Here is a specific explanation:

Reducing vibration transmission: Aluminum auto bearing brackets serve as the support structure for bearings, and their stability and strength are crucial for reducing vibration transmission to the interior of the vehicle body and carriage. When the bearing bracket design is reasonable and the material (such as aluminum alloy) has good rigidity and durability, it can more effectively isolate and absorb vibrations from the road or wheels, reduce the impact of these vibrations on passengers, and thus improve ride comfort.

Reduce noise: Similar to vibration, the state of the bearing bracket can also affect the noise level. A stable and precisely installed bearing bracket can reduce noise caused by bearing failure or improper installation. These noises usually include the buzzing, creaking, or other irregular sounds of bearings, which can interfere with the passenger's riding experience. Therefore, the use of aluminum auto bearing brackets helps to reduce these noises, making the ride more peaceful and comfortable.

Improving driving stability: The stability and strength of the bearing bracket also directly affect the driving stability of the vehicle. A sturdy bearing bracket can ensure the normal operation of the wheels and suspension system, reducing driving instability caused by loose or worn components. This stability is crucial for improving ride comfort, as it reduces the bumps and shakes that passengers may feel during driving.

In summary, the use of aluminum auto bearing brackets indirectly improves ride comfort by reducing vibration transmission, reducing noise, and improving driving stability. However, it should be noted that the improvement of ride comfort is also influenced by various other factors, such as suspension system tuning, seat design and materials, tire selection, etc. Therefore, when evaluating the impact of aluminum auto bearing brackets on ride comfort, these factors should be comprehensively considered.

Can the use of aluminum auto bearing brackets improve safety?

The use of aluminum auto bearing brackets can indeed improve the safety of automobiles, which is mainly reflected in the following aspects:

1、 Enhance structural stability

Supporting and fixing function: As the supporting structure of the bearing, the stability and strength of the aluminum auto bearing bracket directly affect the normal operation of the bearing and even the entire transmission system. A stable bearing bracket can ensure that the bearing maintains the correct position and posture during high-speed rotation, reducing the risk of failure caused by looseness or displacement.

Improve load-bearing capacity: High quality aluminum auto bearing brackets can withstand large loads, ensuring stable operation even under harsh working conditions. This is of great significance for protecting the transmission system and preventing damage caused by overload.

2、 Reduce the risk of malfunctions

Reduce wear and friction: A good fit between aluminum auto bearing brackets and bearings can reduce wear and friction, extending the service life of bearings. Meanwhile, good lubrication and sealing performance can also help reduce bearing failures caused by poor lubrication or impurity invasion.

Improve corrosion resistance: Aluminum alloy materials have good corrosion resistance and can be used for a long time in humid and highly corrosive environments without being easily damaged. This helps to reduce the risk of bearing bracket failure caused by corrosion and ensure the safe operation of the car.

3、 Improve driving stability

Reduce vibration and noise: As mentioned earlier, the stability and accuracy of aluminum auto bearing brackets help reduce the transmission of vibration and noise. This not only improves ride comfort, but also reduces the risk of driver distraction or fatigue caused by excessive vibration and noise.

Improving handling performance: A stable bearing bracket helps ensure the normal operation of the wheels and suspension system, thereby improving the handling performance of the car. This is of great significance for improving driving safety and reducing traffic accidents caused by improper handling.

In summary, the use of aluminum auto bearing brackets improves the safety of automobiles by enhancing structural stability, reducing the risk of failure, and enhancing driving stability. However, it should be noted that the safety of a car is also affected by various factors, such as the driver's driving skills, the maintenance status of the vehicle, road conditions, etc. Therefore, in the process of ensuring the safety of automobiles, it is necessary to comprehensively consider various factors and take corresponding measures.

In addition, with the continuous development of auto technology, the manufacturing process and material properties of aluminum auto bearing brackets are also constantly improving. In the future, with the application of more advanced materials and technologies, the safety and reliability of aluminum auto bearing brackets will be further improved.

Address Dalun Mould Venture Park, Beilun, Ningbo, Zhejiang, China

Tel +86 13586867000

E-mail cindy@youyuandiecasting.com

2021 © All Rights Reserved by Ningbo Beilun Youyuan Machinery Manufacturing Co., Ltd. Aluminum Auto Bearing Bracket manufacturers custom Aluminum Auto Bearing Bracket suppliers

English

English русский

русский Español

Español