Web Menu

Product Search

Exit Menu

Product Series

Aluminum Bearing Bracket

- Description

- Contact Us

Related Products

-

Rice Transplanter Spare Parts

Cat:Aluminum Die Casting

Our Rice Transplanter Spare Parts are designed for efficient rice cultivation. This component is equ...

See Details -

Aluminum Die Casting Thermostat

Cat:Aluminum Die Casting

Renowned for their precision and efficiency, these Aluminum die-casting that are crafted using the i...

See Details -

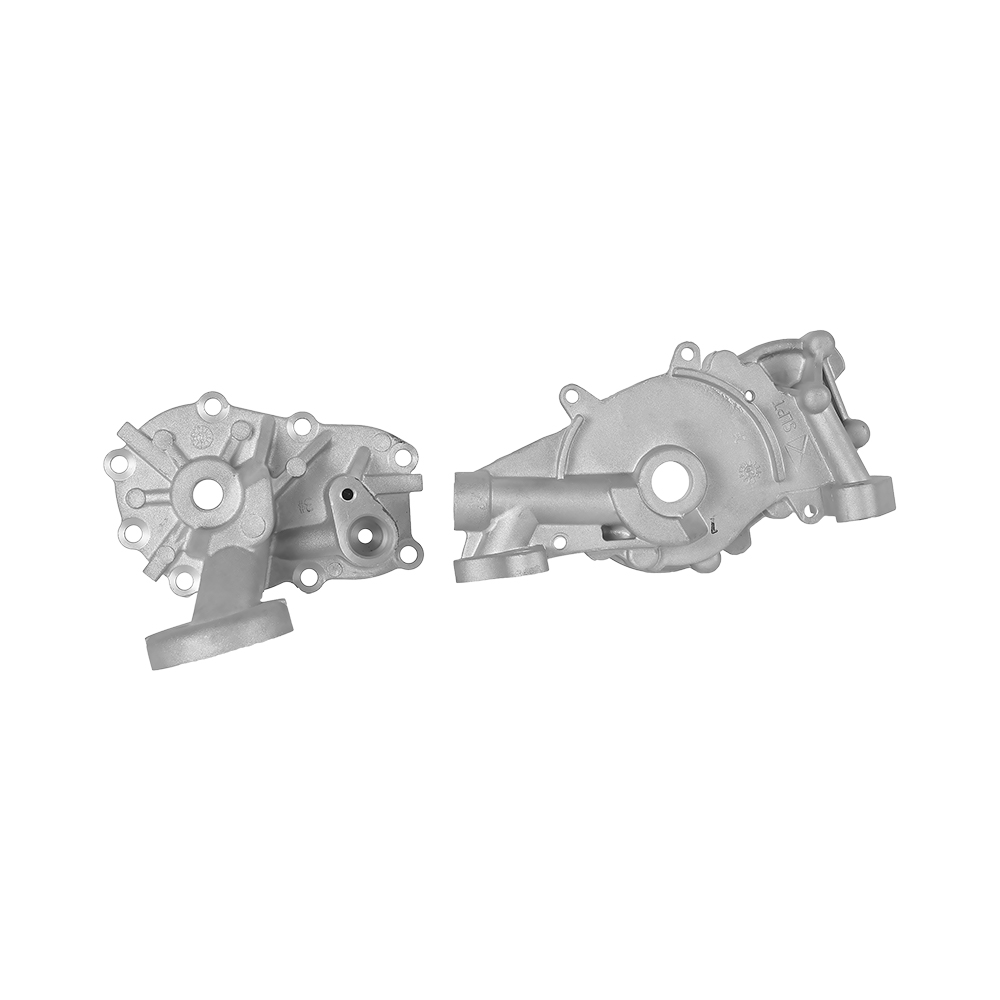

Automobile Engine Water Pump

Cat:Aluminum Die Casting

The automobile engine water pump is a critical component within the intricate machinery of a vehicle...

See Details -

Cam Crank Angle Sensor Casing

Cat:Aluminum Die Casting

The Cam Crank Angle Sensor (also known as Camshaft or Crankshaft Position Sensor) casing refers to t...

See Details -

Engine Cooling Car Accessories

Cat:Aluminum Die Casting

Engine Cooling Car Accessories is a metal component specifically designed for the automotive engine ...

See Details -

Auto Parts Car Engine Oil Pump

Cat:Aluminum Die Casting

Our car engine oil pump is crafted from high-quality aluminum, undergoing precision processing and s...

See Details -

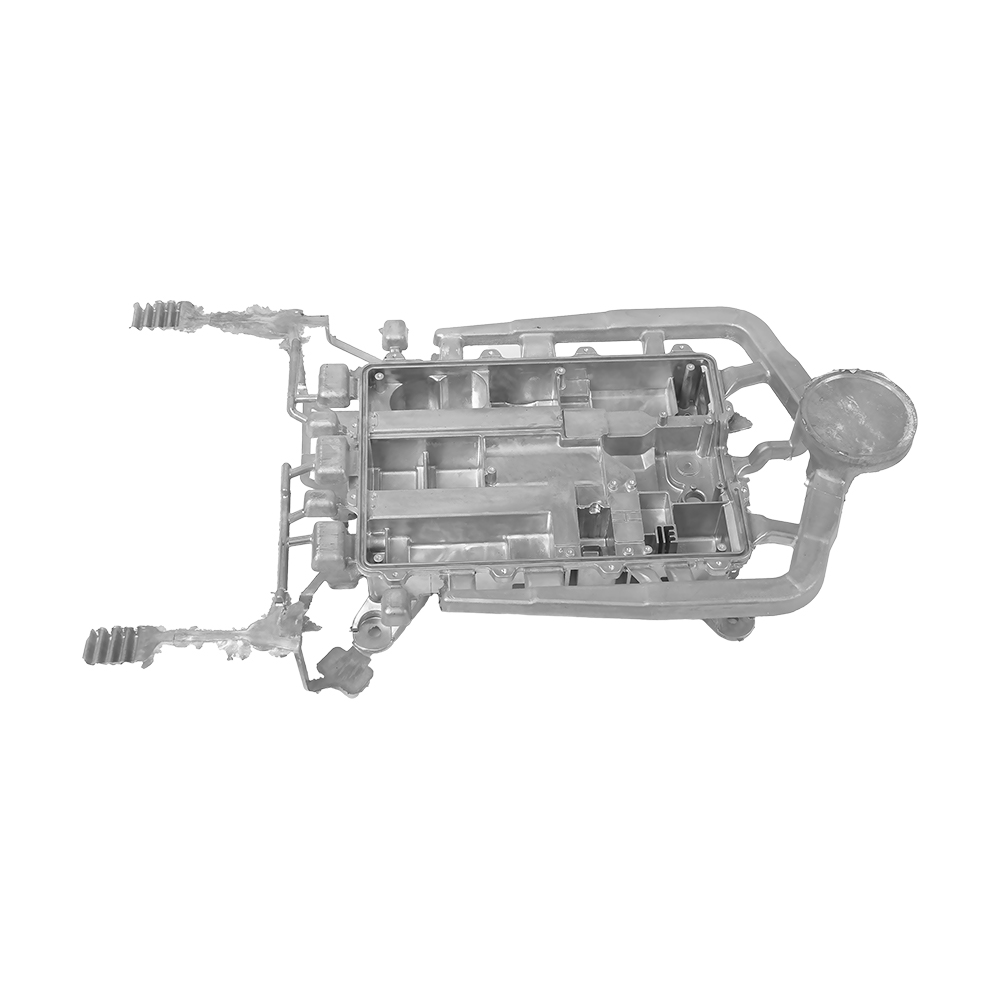

Aluminum Die Casting Gearbox Body

Cat:Aluminum Die Casting

High Precision: Utilizing precision aluminum alloy die-casting technology ensures the product's dime...

See Details -

Brushless Motor Accessories

Cat:Aluminum Die Casting

Our brushless motor accessories are crafted from high-quality metal materials, undergoing meticulous...

See Details -

Auto Engine Cooling Heat Dissipation Cover, End Cover

Cat:Aluminum Die Casting

This Auto Engine Cooling Heat Dissipation Cover and End Cover are CNC machined from high-quality met...

See Details -

30 Valves

Cat:Aluminum Die Casting

30 valve body usually refers to the valve body material of 30 steel valve, this type of valve is oft...

See Details

As a professional a China custom Aluminum Bearing Bracket manufacturers and Aluminum Bearing Bracket suppliers, The company currently has fixed assets of about 10 million die-casting, CNC and intelligent processing equipment, an annual output value of about 30 million. We have been indirectly supporting the production of aluminium products for well-known domestic enterprises for many years. There are Huawei base station lifting ground cylinders, Jiangsu radio factory military satellite phone aluminium parts, Nanjing Fuleiwei agricultural machinery rice transplanter parts, Beilun Top brushless car motor parts and so on.

-

The Role of Permanent Molds in Die Casting Yes, die casting strictly utilizes permanent molds, which are typically crafted from high-strength heat-resistant steel. Unlike sand casting or investment c...

READ MORE -

Regarding whether die casting or CNC machining is cheaper, the answer actually depends on how many parts you plan to produce.It's like printing flyers: if you only need one, handwriting is the cheapes...

READ MORE -

Many people might find the term "die cast" a little strange when they hear it for the first time: doesn't "die" mean "death" in English? In fact, in industrial manufacturing, this word has a completel...

READ MORE

Can aluminum bearing brackets withstand large loads?

Aluminum bearing brackets can withstand a certain range of large loads when designed and manufactured properly. However, its specific load-bearing capacity will be affected by various factors, such as the grade of aluminum alloy, heat treatment status, geometric shape, size, wall thickness, design of reinforcement bars, and installation and use conditions of the bracket.

Aluminum alloy materials themselves have high specific strength and good toughness, which enables them to provide a certain load-bearing capacity while ensuring a certain degree of lightweight. However, compared to some higher strength metal materials such as steel, the load-bearing capacity of aluminum alloys may be relatively limited.

In order to improve the load-bearing capacity of aluminum bearing brackets, the following measures are usually taken:

Optimization design: Disperse and bear the load through reasonable structural design, such as increasing the wall thickness of the bracket, setting reinforcement bars, etc.

Choosing the appropriate aluminum alloy grade: Different grades of aluminum alloys have different mechanical properties, and choosing the appropriate grade can ensure that the bracket has sufficient load-bearing capacity.

Fine Manufacturing: Adopting advanced manufacturing processes and equipment to ensure the dimensional accuracy and internal quality of the bracket, reducing defects and stress concentration.

Appropriate heat treatment: Heat treatment of aluminum alloys can improve their mechanical properties and enhance their load-bearing capacity.

Reasonable installation and use: The correct installation method and usage conditions are also important factors in ensuring the load-bearing capacity of aluminum bearing brackets.

In summary, aluminum bearing brackets can withstand certain large loads, but the specific load-bearing capacity needs to be evaluated and designed according to the actual situation. When designing and selecting aluminum bearing brackets, full consideration should be given to their usage environment and requirements to ensure that the brackets can operate safely and reliably.

Do aluminum bearing brackets need to be lubricated before installation?

There is no absolute answer to whether lubricating oil needs to be applied to aluminum bearing brackets before installation, as it depends on various factors including the specific type of aluminum bearing bracket, usage environment, design requirements, and manufacturer's recommendations.

General situation

In most cases, aluminum bearing brackets do not require special lubrication before installation. Because bearings themselves usually contain lubricating grease or oil, these lubricants can provide necessary lubrication and cooling effects during bearing operation. However, during the installation process, in order to ensure the smooth installation of bearings and brackets, a small amount of lubricating oil is sometimes applied to the surface of the shaft or bearing body to reduce friction and prevent collision.

exceptional case

Special requirements: If the design or usage environment of the aluminum bearing bracket has special requirements, such as higher lubrication performance or longer service life, the manufacturer may explicitly require the application of specific lubricating oil or grease before installation in the manual or technical documents.

Cleanliness requirement: Before installation, it is necessary to ensure the cleanliness of the bearings and brackets to avoid impurities such as dust and oil from entering. If there is rust proof oil or other protective coating on the surface of the bearing, it may be necessary to clean it with a suitable solvent and apply lubricating oil as needed after cleaning.

Lubrication method: Different bearings and supports may use different lubrication methods, such as grease lubrication, oil bath lubrication, or oil spray lubrication. When choosing a lubrication method, it is necessary to comprehensively consider factors such as the type of bearing, speed, load, and working environment.

matters needing attention

Follow manufacturer's recommendations: When installing aluminum bearing brackets, the manufacturer's recommendations and instructions should be followed first to ensure proper installation and use.

Maintain cleanliness: During installation, ensure the cleanliness of bearings and brackets to avoid contamination and impurities from entering.

Choose the appropriate lubricating oil: If lubricating oil needs to be applied, choose the lubricating oil suitable for the bearings and brackets, and follow the correct application method and dosage.

In summary, whether lubricating oil needs to be applied to the aluminum bearing bracket before installation depends on the specific situation for judgment and decision-making. In most cases, following the manufacturer's recommendations and instructions is sufficient. If lubricating oil needs to be applied, appropriate lubricating oil should be selected and the correct application method should be followed.

Address Dalun Mould Venture Park, Beilun, Ningbo, Zhejiang, China

Tel +86 13586867000

E-mail cindy@youyuandiecasting.com

2021 © All Rights Reserved by Ningbo Beilun Youyuan Machinery Manufacturing Co., Ltd. Aluminum Bearing Bracket manufacturers custom Aluminum Bearing Bracket suppliers

English

English русский

русский Español

Español