Web Menu

Product Search

Exit Menu

Product Series

Hydraulic Brake Pump

- Description

- Contact Us

Related Products

-

Motorcycle Crankcase

Cat:Aluminum Die Casting

The motorcycle crankcase is a crucial component in the internal combustion engine system, serving as...

See Details -

Aluminum Die Casting Thermostat

Cat:Aluminum Die Casting

Renowned for their precision and efficiency, these Aluminum die-casting that are crafted using the i...

See Details -

Cam Crank Angle Sensor Casing

Cat:Aluminum Die Casting

The Cam Crank Angle Sensor (also known as Camshaft or Crankshaft Position Sensor) casing refers to t...

See Details -

Engine Cooling Car Accessories

Cat:Aluminum Die Casting

Engine Cooling Car Accessories is a metal component specifically designed for the automotive engine ...

See Details -

Auto Engine Aluminum Water Pump

Cat:Aluminum Die Casting

Auto Engine Aluminum Water Pump is a high-performance aluminum water pump designed specifically for ...

See Details -

Aluminum Auto Bearing Bracket

Cat:Aluminum Die Casting

Aluminum Automatic Bearing Bracket is a mechanical component designed specifically for modern indust...

See Details -

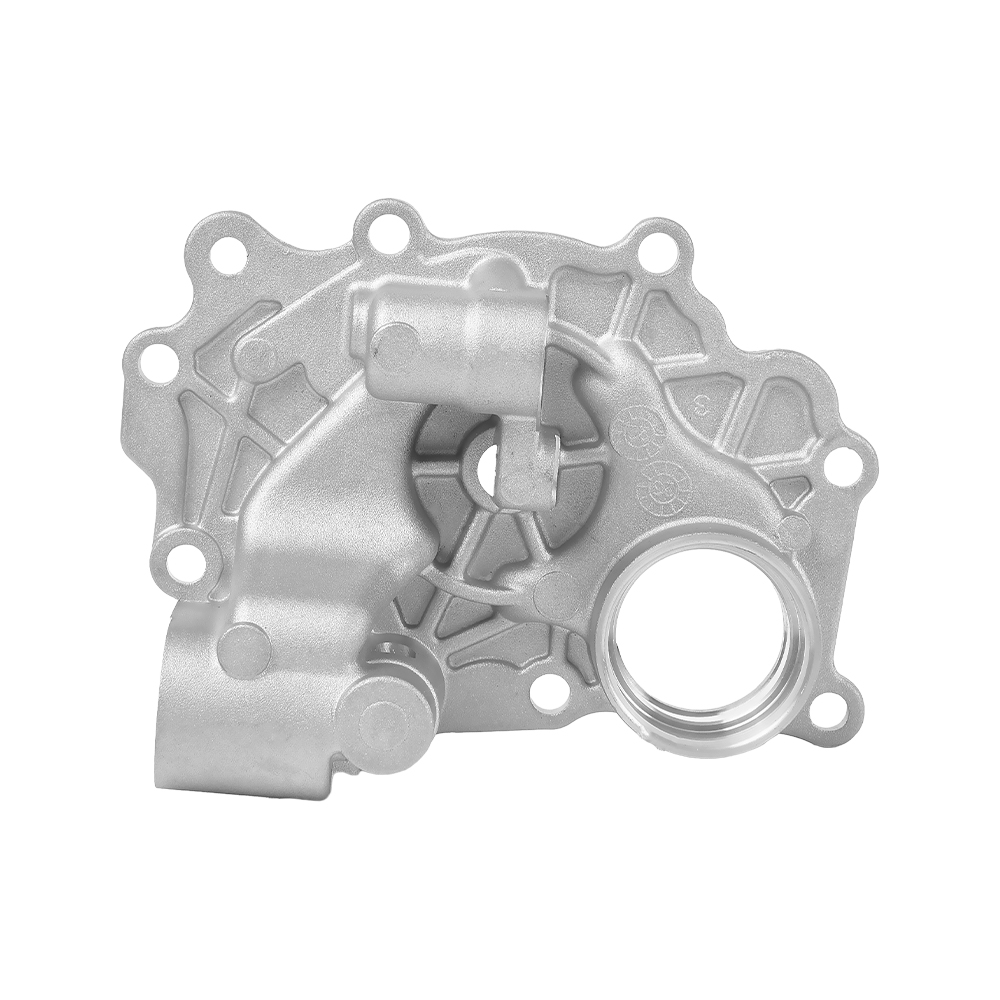

Car Oil Pump Cover

Cat:Aluminum Die Casting

This Engine Oil Pump Cover is specifically designed for automotive engines, aiming to provide outsta...

See Details -

Medical Device Accessories

Cat:Aluminum Die Casting

In the medical field, medical device accessories have a vital role in the normal operation and use t...

See Details -

Opening Machine Accessories

Cat:Aluminum Die Casting

Aluminum pressure casting is the main part of the aluminum pressure die-casting machine, manufacture...

See Details -

30 Valves

Cat:Aluminum Die Casting

30 valve body usually refers to the valve body material of 30 steel valve, this type of valve is oft...

See Details

As a professional a China custom Hydraulic Brake Pump manufacturers and Hydraulic Brake Pump suppliers, The company currently has fixed assets of about 10 million die-casting, CNC and intelligent processing equipment, an annual output value of about 30 million. We have been indirectly supporting the production of aluminium products for well-known domestic enterprises for many years. There are Huawei base station lifting ground cylinders, Jiangsu radio factory military satellite phone aluminium parts, Nanjing Fuleiwei agricultural machinery rice transplanter parts, Beilun Top brushless car motor parts and so on.

-

Direct Answer: Is Die Casting Strong? Yes, die casting produces exceptionally strong parts that often exceed the strength of plastic injection molding and rival the structural integrity of some forge...

READ MORE -

Direct Answer: Is Die Cast Healthy and Safe? Generally speaking, products made through die casting are considered healthy and safe for everyday use, provided they meet international safety standards ...

READ MORE -

The Role of Permanent Molds in Die Casting Yes, die casting strictly utilizes permanent molds, which are typically crafted from high-strength heat-resistant steel. Unlike sand casting or investment c...

READ MORE

Can a hydraulic brake pump convert the force of the brake pedal into hydraulic energy in the brake system?

The hydraulic brake pump can indeed convert the force of the brake pedal into hydraulic energy in the braking system.

The hydraulic brake pump is a key component in the automotive braking system, and its working principle is as follows:

When the driver steps on the brake pedal, the pedal pushes the piston in the brake master cylinder (or master cylinder) forward through a mechanical connection.

The movement of the piston generates pressure in the brake fluid inside the master cylinder, which is transmitted to each brake cylinder (or wheel cylinder) through the oil pipe.

In the brake cylinder, pressure pushes the piston outward, which in turn pushes the brake pads in the brake shoes or calipers into contact with the brake drum or brake disc, generating friction and thus achieving braking of the wheels.

Therefore, the hydraulic brake pump converts the force of the driver pressing the brake pedal into the pressure of the brake fluid through the movement of the piston and master cylinder, and transmits it to various parts of the braking system, ultimately achieving the braking of the vehicle.

This process not only ensures the timeliness and effectiveness of vehicle braking, but also through the transmission characteristics of the hydraulic system, the braking force is evenly distributed between the wheels, improving the stability and safety of braking.

In summary, hydraulic brake pumps play a crucial role in the braking system, effectively converting the force of the brake pedal into hydraulic energy and providing a reliable source of power for vehicle braking.

Can the hydraulic brake pump be under high load for a long time?

It is not recommended to keep the hydraulic brake pump in a high load state for a long time. The following is a detailed analysis:

1、 The impact of high load conditions

Temperature increase:

When the hydraulic brake pump is in a high load state for a long time, the temperature of the pump body and its surrounding components will gradually increase due to friction and hydraulic energy conversion. Excessive temperature not only affects the lubrication and sealing performance of pump components, but may also accelerate material aging and wear, and even lead to problems such as hydraulic oil deterioration and bubble formation, thereby affecting the stability and reliability of the braking system.

Increased wear and tear:

High load operation will exacerbate the wear of internal components of hydraulic brake pumps, especially key components such as pistons, cylinder bodies, and seals. Long term wear and tear can lead to increased clearance between parts, decreased sealing performance, resulting in oil leakage, insufficient pressure, and other faults, seriously affecting the performance of the braking system.

Unstable pressure:

Under high load conditions, the hydraulic brake pump may not be able to maintain a stable output pressure. The instability of pressure will directly affect the response speed and braking effect of the braking system, increasing the unsafe factors of vehicle driving.

Reduce lifespan:

Long term high load operation will significantly shorten the service life of hydraulic brake pumps. Due to the cumulative effects of wear, aging, and other factors, the performance of the pump will gradually decline until it cannot meet the requirements of the braking system.

2、 Measures to avoid high load conditions

Reasonable driving:

Drivers should develop good driving habits and avoid frequent high-intensity braking operations such as sudden braking. This can reduce the load and wear of the hydraulic brake pump, and extend its service life.

Regular inspection and maintenance:

Regular inspection and maintenance of the hydraulic brake pump and its related components are key to ensuring its normal operation. The inspection includes the quality and quantity of brake fluid, the integrity of seals, and the tightness of the pump body and connecting components. At the same time, it is necessary to regularly replace hydraulic oil and worn parts to maintain the good condition of the braking system.

Use high-quality hydraulic oil:

The quality of hydraulic oil has a significant impact on the performance and lifespan of hydraulic brake pumps. Using high-quality hydraulic oil can reduce viscosity changes, minimize the formation of sludge and sediment, and thus maintain the cleanliness and stability of the hydraulic system.

Optimize system design:

In the design and manufacturing process of automobiles, the working load and working environment of hydraulic brake pumps should be fully considered. By optimizing system design and selecting more durable materials, the load-bearing capacity and service life of hydraulic brake pumps can be improved. For example, adopting advanced hydraulic control technology and improving the performance of seals.

In summary, it is not recommended to keep the hydraulic brake pump in a high load state for a long time. In order to ensure its normal operation and extend its service life, a series of measures need to be taken to avoid high load operation and maintain the good condition of the braking system.

Address Dalun Mould Venture Park, Beilun, Ningbo, Zhejiang, China

Tel +86 13586867000

E-mail cindy@youyuandiecasting.com

2021 © All Rights Reserved by Ningbo Beilun Youyuan Machinery Manufacturing Co., Ltd. Hydraulic Brake Pump manufacturers custom Hydraulic Brake Pump suppliers

English

English русский

русский Español

Español