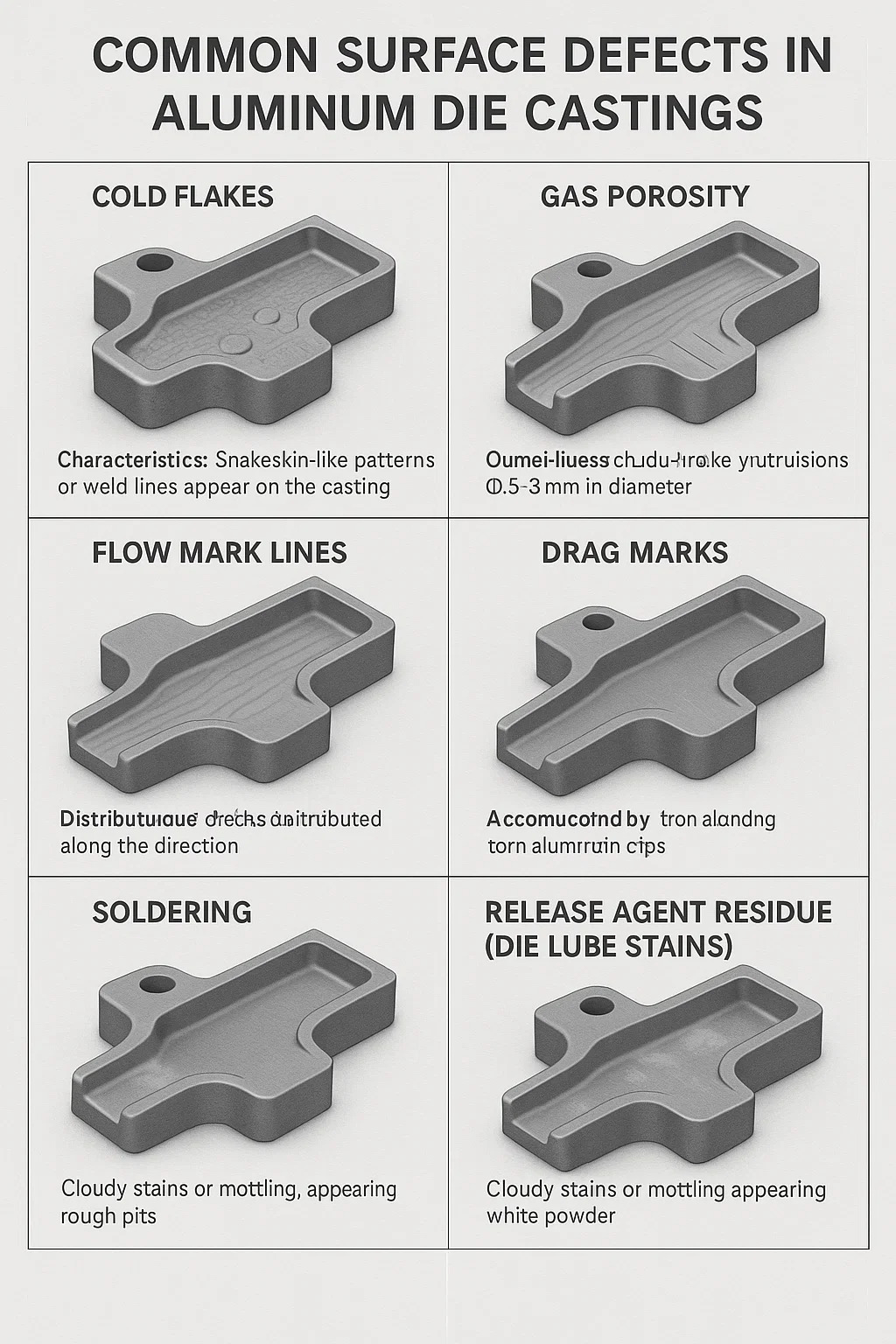

Detailed Explanation of Common Surface Defects in Aluminum Die Castings

1. Cold Flakes

Characteristics: Snakeskin-like patterns or weld lines appear on the casting surface, and the surface feels uneven.

Cause: Low molten aluminum temperature or slow injection speed, resulting in a failure of the two aluminum streams to fuse.

Damage: Sharp decrease in structural strength, especially in thin-walled areas prone to cracking.

2. Gas Porosity

Characteristics: Smooth, bubble-like protrusions (0.5-3mm in diameter) appear on the surface, which rupture to reveal holes.

Causes:

Poor mold venting (blocked ejector pins/parting surface)

Excessive release agent vapor generation

High-risk areas: Roots of ribs and tops of closed cavities.

3. Drag Marks

Characteristics: Long, linear scratches along the draft direction, sometimes accompanied by torn aluminum chips.

Causes:

Insufficient draft angle (e.g., less than 1°)

Scratches or insufficient polishing on the mold cavity surface.

4. Flow Marks Lines

Characteristics: Wavy color streaks distributed along the direction of molten aluminum flow

Causes:

Improper gate design leading to turbulent flow

Aluminum temperature stratification (rapid surface cooling)

5. Heat Checking

Characteristics: A network of microcracks, often occurring in the thick-thin transition zone

Causes:

Local mold overheating (failed cooling water system)

Premature ejection, incomplete solidification of the part interior

6. Soldering

Characteristics: The casting surface adheres to the mold steel, forming rough pits

Causes:

Direct aluminum impaction on the mold steel (e.g., direct gate impaction on the core)

Abrasion of the mold surface coating

7. Release Agent Residue (Die Lube Stains)

Characteristics: Cloudy stains or white powder, mottling after anodizing

Causes:

Poor atomization of the spray, resulting in accumulation in corners

Incomplete removal during the air blowing process

English

English русский

русский Español

Español